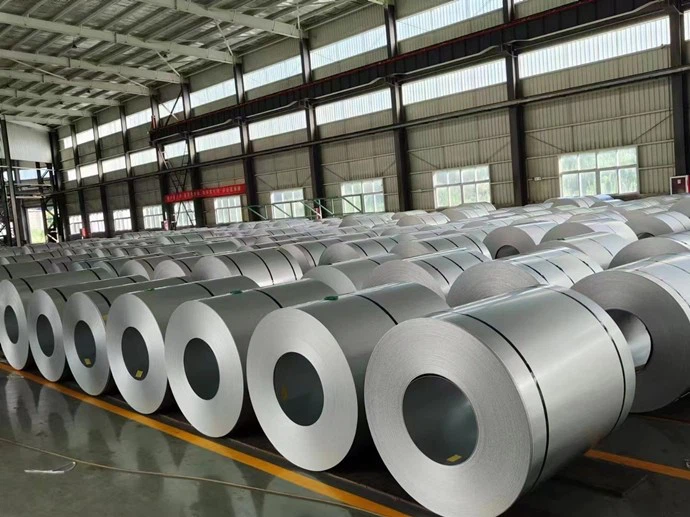

لفائف الصلب الجالفالوم

مُصنِّع محترف لفائف الصلب الغالفالوم

لفائف الفولاذ المجلفن لها مواصفات وأحجام كاملة، مع أداء جيد ضد التآكل وقابلية المعالجة، وتستخدم على نطاق واسع في مجالات البناء والديكور وتصنيع الأجهزة المنزلية، إلخ. بالإضافة إلى ذلك، فهي أيضًا المادة الخام للصفائح الفولاذية المجلفنة، وألواح/ألواح السقف المجلفنة، وألواح لفائف الصلب المطلية مسبقًا، والتي يمكن معالجتها بعمق عن طريق القطع والتشكيل والطلاء وما إلى ذلك.

مقاومة التآكل

تتميز لفائف الألوزينك الفولاذية بمقاومة قوية للتآكل، ويمكن أن يصل عمرها التشغيلي العادي إلى 25 عامًا، وهو أطول من اللوح المجلفن بمقدار 3-6 مرات، ويمكن مقارنته بالفولاذ المقاوم للصدأ.

مقاومة الحرارة

تتميز ألواح فولاذ الألزينك بدرجة عالية من الانعكاسية الحرارية وهي مناسبة كمادة تسقيف. كما تتميز ألواح الصلب المصنوعة من سبائك الزنك نفسها بمقاومة ممتازة للحرارة ويمكن استخدامها في البيئات ذات درجات الحرارة العالية التي تصل إلى 315 درجة.

قابلية ممتازة لإعادة الطلاء

(التصاق غشاء الطلاء) يمكن للصفائح المجلفنة أن تحافظ على التصاق جيد بغشاء الطلاء ويمكن رشها مباشرةً أو رشها بالمسحوق دون معالجة مسبقة خاصة.

قابلية معالجة جيدة

(القص، الختم، اللحام النقطي، اللحام النقطي، اللحام بالدرز) تتميز صفائح الفولاذ الجالفالوم بخصائص معالجة ممتازة ويمكن ثقبها وقصها ولحامها وما إلى ذلك. يتميز الطلاء بالالتصاق الجيد ومقاومة الصدمات

| اسم المنتج | لفائف الصلب الجالفالوم |

| سماكة | 0.12 مم - 6.00 مم |

| عرض | 20 مم - 1500 مم |

| طول | 1 م - 12 م، دعم التخصيص |

| معيار | AISI و ASTM و DIN و DIN و JIS و GB و JIS و SUS و EN، إلخ. |

| سماكة طلاء الألومنيوم بالزنك | 15-275 جم/م² |

| محتوى الطلاء بالزنك | Al: 55%، Zn: 43.5%، Si: 1.5% |

آل | زنك | سي | في | النحاس | قرص مضغوط | باء باء | سن | ني | إغلاق Cr |

55-58 | 41-43 | 1.5-2 | 0.25 | 0.03 | 0.05 | 0.01 | 0.05 | 0.05 | 0.05 |

درجة | قوة الخضوع MPa≥ | قوة الشد MPa≥ | الاستطالة A%≥ |

Dx51D Z/ZM/ZM/az/AM | 240-380 | 270-500 | 22 |

Dx52D Z/ZM/ZM/az/AM | 140-300 | 270-420 | 26 |

Dx53D Z/ZM/ZM/az/AM | 140-260 | 270-380 | 30 |

Dx54D Z/ZM/ZM/az/AM | 120-220 | 260-350 | 36 |

S220GD Z/ZM/AM | 220 | 300 | 20 |

S250GD Z/ZM/ZM/az/AM | 250 | 330 | 19 |

S280GDZ/ZM/AM | 280 | 360 | 18 |

S300GD A/AM | 300 | 380 | 18 |

S320GDZ/ZM/AM | 320 | 390 | 17 |

S350GD Z/ZM/ZM/az/AM | 350 | 420 | 16 |

S450GD A/AM | 450 | 480 | 15 |

S550GD Z/ZM/ZM/az/AM | 550 | 550 | - |

| نوع الطلاء | وزن الطلاء الموصى به |

| سبائك الألومنيوم والزنك | 30/40/50/60/75/90/100/150 |

| ج: جودة الطلاء50 جم/㎡، يساوي تقريبًا سمك الطلاء13.3 مساءً | |

| المشروع | التصنيف | الرمز |

| نوع الطلاء | سبائك الألومنيوم والزنك | من الألف إلى الياء |

| تشطيب السطح | الترتر التقليدي | R |

| تقليل الترتر إلى الحد الأدنى | M | |

| الجلد من خلال | س | |

| معالجة السطح | التخميل بالكرومات | ج |

| التخميل غير الكروماتي | C5 | |

| تخميل وتخميل الكرومات | ثاني أكسيد الكربون | |

| التخميل الخالي من الكروم | CO5 | |

| مضاد للبصمات | ن | |

| خالية من الكرومات/مضادة لبصمات الأصابع | N5 | |

| عدم وجود بصمة كرومات عالية مقاومة للعوامل الجوية | شمال غرب | |

| تعبئة الزيت | 0 | |

| لا يوجد علاج | U |

المعيار الصيني | المعايير الأوروبية | أمريكان ستاندرد | المعيار الياباني |

DC51D+AZ | DX51D+AZ | CS النوع ب، النوع ج | SGLCC |

DC52D+AZ | DX52D+AZ | دس | SGLCD |

S250GD+AZ | S250GD+AZ | 255 | - |

S300GD+AZ | - | - | - |

S350GD+AZ | S350GD+AZ | 345 | الفئة1 SGLC490 |

S550GD+AZ | S550GD+AZ | 550 | SGLC570 |

ما هي لفائف الصلب المجلفن؟

يتكون ملف الفولاذ الغالفالوم من 551 تيرابايت 3 تيرابايت ألومنيوم، و43.41 تيرابايت 3 تيرابايت زنك، و1.61 تيرابايت 3 تيرابايت سيليكون.

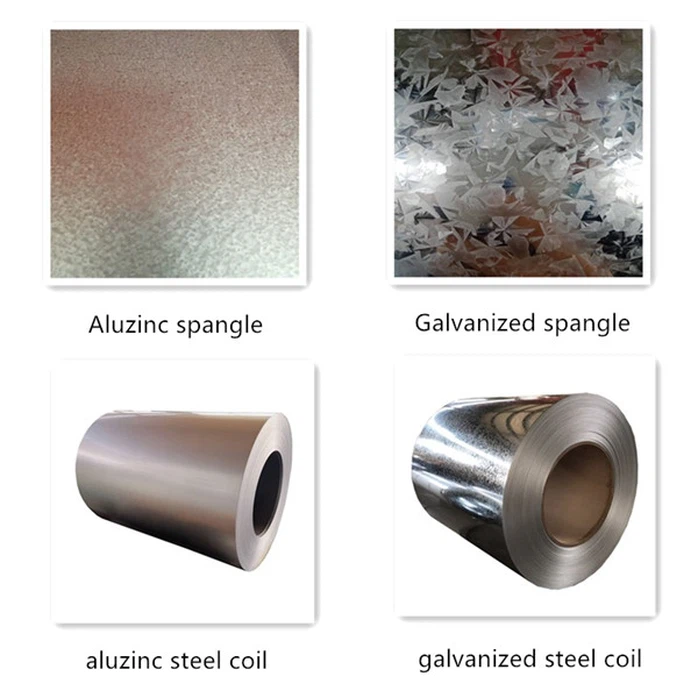

يتميز سطح الملف الفولاذي المصنوع من الفولاذ الجالفالوم بزهرة نجمية فريدة من نوعها ناعمة ومسطحة ورائعة، واللون الأساسي أبيض فضي. هيكل الطلاء الخاص يمنحها مقاومة ممتازة للتآكل. يمكن أن يصل عمر الخدمة العادي لصفائح الجالفالوم إلى 25 عامًا. تتمتع بمقاومة جيدة للحرارة ويمكن استخدامها في البيئات ذات درجات الحرارة العالية التي تصل إلى 315 درجة مئوية. يتميز الطلاء بالالتصاق الجيد بطبقة الطلاء ويتمتع بأداء معالجة جيد، ويمكن ختمه وقصه ولحامه وما إلى ذلك؛ التوصيل السطحي جيد جدًا.

ما الفرق بين المجلفن والألوزنك؟

1. الطلاء: الصفائح المجلفنة هي أساسا صفائح الزنك على الطلاء. يتكون الطلاء السطحي لملف فولاذ الألوزينك من 55% من الألومنيوم، و43.4% من الزنك، و1.6% من السيليكون.

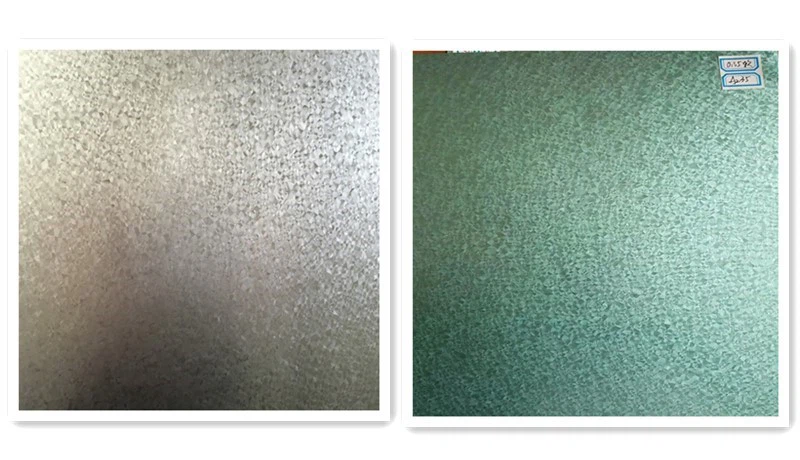

2. وتحدد العناصر النزرة في الطلاء السطحي للصفائح المجلفنة وصفائح الجلفنة والزنك تلألؤاتها المختلفة. فالعناصر المتلألئة على سطح الصفائح المجلفنة هي عناصر متلألئة كبيرة أو صفرية بينما العناصر المتلألئة على سطح الألوزينك هي عناصر متلألئة صغيرة.

3. الأداء المضاد للتآكل لملف الفولاذ المجلفن أفضل. تكون تأثيرات التآكل الذاتي والحاجز لطبقة سبائك الألومنيوم والزنك أقوى، والتي يمكن أن تحمي الفولاذ في البيئات القاسية وتطيل عمر الخدمة. العمر التشغيلي العادي لصفائح الجلفنة هو عمر الخدمة العادي للصفائح المجلفنة العادية. 2-6 مرات.

الفرق بين مكافحة الإصبع والتخميل

لماذا تختار لفائف الفولاذ الغالفالوم الخاصة بنا؟

لدينا القدرة على توريد AZ165 galvalume لتلبية متطلبات العملاء للاستخدام في المناطق شديدة التآكل. نحن نضمن أن يكون وزن مالطلاء المعدني لا يقطع الزوايا، ولدينا المعدات اللازمة لاكتشاف ذلك.

تقنية الطلاء المبتكرة

تتميز لفائف جالفالوم الفولاذية بطبقة فريدة من سبائك الألومنيوم والزنك تجمع بين أفضل خصائص كلا المعدنين. لا يعزز هذا الطلاء المبتكر من متانة اللفائف فحسب، بل يوفر أيضاً انعكاسية فائقة للحرارة، مما يجعله حلاً مثالياً للمباني الموفرة للطاقة.