مُصنِّع لفائف الصلب المجلفن

المصنع الأكثر ثقة -- لفائف الصلب المجلفن

لفائف الفولاذ المجلفن لها مواصفات وأحجام كاملة، مع أداء جيد ضد التآكل وقابلية المعالجة، وتستخدم على نطاق واسع في مجالات البناء والديكور وتصنيع الأجهزة المنزلية، إلخ. بالإضافة إلى ذلك، فهي أيضًا المادة الخام للصفائح الفولاذية المجلفنة، وألواح/ألواح السقف المجلفنة، وألواح لفائف الصلب المطلية مسبقًا، والتي يمكن معالجتها بعمق عن طريق القطع والتشكيل والطلاء وما إلى ذلك.

مواصفات لفائف الصلب المجلفن

المواد | SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D, etc |

|---|

| سماكة | 0.12 مم - 6 مم |

| عرض | العرض التقليدي الذي يقل عن 0.5 مم هو 1000 مم، 1200 مم، وما فوقه هو 1000، 1250 مم |

| وزن الملف | 8-10 أطنان/مخصص |

| التسامح | “+/-0.02 مم |

| نوع الركيزة | لفائف مدرفلة على الساخن، لفائف مدرفلة على البارد |

| هيكل السطح | البقع الصفرية، البقع الصغيرة، البقع الصغيرة، البقع العادية، البقع الكبيرة |

| سُمك طبقة الزنك | 30 جم/㎡ - 275 جم/㎡ (Z275/G90) |

| معيار | AISI، AISI، ASTM، BS، GB، JIS |

| معايير التنفيذ | gb/t2518 gb/t25052، en10346، jis g3302، astma653 |

| الشهادات | SGS, ISO 9001, CE |

ميزات لفائف الصلب المجلفن

بالإضافة إلى مواصفات الفولاذ GI، وفقًا لعملية الجلفنة، يمكن تقسيم الملفات المجلفنة إلى فئتين، الجلفنة بالغمس الساخن والجلفنة الكهربائية. سعر لفائف الصلب المجلفن بالغمس على الساخن أرخص من اللفائف المجلفنة بالكهرباء. عملية الغمس على الساخن أقل تكلفة، ولكن طلاء الزنك بالغمس الساخن أكثر سمكًا ويتميز بمقاومة أفضل للتآكل. اتصل بنا للحصول على سعر أكثر ملاءمة لمشروعك!

فولاذ مجلفن كهربائيًا

تُعد شركة Yeson Steel موردًا رائدًا للصلب المجلفن والصلب المطلي بالألوان. نحن نوفر منتجات الصلب المجلفن عالية الجودة للعملاء في مجالات البناء والتصنيع والصناعات الأخرى، ومن بينها الصلب المجلفن بالكهرباء والصلب المجلفن بالغمس الساخن الذي تم تصديره إلى أكثر من مائة دولة، مثل تركيا والإمارات العربية المتحدة والمملكة العربية السعودية والبرازيل وشيلي وليبيا وماليزيا وغيرها.

الفولاذ المجلفن بالغمس الساخن

الفولاذ المجلفن بالغمس على الساخن هو فولاذ GI فعال للغاية من حيث التكلفة مع تكلفة معالجة منخفضة وطلاء زنك أكثر سمكًا، ومقاومة جيدة للصدأ للبيئات الخارجية. Yeson Steel هي شركة محترفة لتصنيع الفولاذ المجلفن مع خطين من الفولاذ المجلفن، وأسرع وقت للتسليم هو 5 أيام، ونحن نخدم أكثر من 100 دولة، مثل الفلبين وماليزيا والمملكة العربية السعودية والإمارات العربية المتحدة وكولومبيا، إلخ.

الصلب المجلفن المطلي مسبقًا

عند استخدام مكونات الصلب لصنع منتجات نهائية أكثر تعقيدًا، يمكن جلفنتها قبل تجميع المنتج. وهذا ما يسمى الجلفنة المسبقة أو "الجلفنة المسبقة". وقد يُشار إليها أيضًا باسم الجلفنة "المدمجة" أو "المستمرة" أو "المدرفلة". وبصورة أساسية، يتم جلفنة مكونات الصلب (مثل الصفائح أو الأسلاك) باستخدام جهاز آلي.

أنواع لفائف الصلب المجلفن

مقاومة عالية للتآكل

تصنع اللفائف المجلفنة عن طريق طلاء الزنك على سطح لفائف الصلب. يتمتع الزنك بمقاومة جيدة للتآكل ويمكنه منع تآكل لفائف الصلب بشكل فعال من التآكل في بيئات مثل الرطوبة والأحماض القوية والقلويات القوية، وبالتالي إطالة عمر خدمة الصلب.

قابلية معالجة جيدة

تتميز الملفات المجلفنة بمرونة جيدة ويمكن معالجتها وتشكيلها بسهولة. على سبيل المثال، في مجال الإنشاءات، يمكن ثنيها وتثقيبها وتقطيعها بسهولة لتلبية احتياجات التصميم المختلفة

المظهر الجميل

يتميز الملف المجلفن بمظهر مشرق وسلس وله خصائص زخرفية جيدة. يستخدم على نطاق واسع في البناء، والتطبيقات المنزلية وغيرها من المجالات، ويمكن أن يعطي المنتجات تأثيرات بصرية أفضل.

عمر خدمة طويل

نظرًا لأن اللفائف المجلفنة تتمتع بمقاومة ممتازة للتآكل، فإن عمرها التشغيلي طويل نسبيًا. في الوقت نفسه، تتمتع الملفات المجلفنة أيضًا بمقاومة قوية للزلازل ومقاومة الرياح وغيرها من الخصائص، والتي يمكن أن تضمن استقرارها وسلامتها في البيئات القاسية.

ما هي لفائف الصلب المجلفن؟

لفائف مجلفنة، لفائف فولاذية رقيقة يتم غمرها في حمام من الزنك المنصهر بحيث تلتصق طبقة من الزنك بالسطح. يتم إنتاجه بشكل أساسي عن طريق عملية الجلفنة المستمرة، أي أن الملف الصلب المدلفن يتم غمره باستمرار في حمام طلاء يحتوي على الزنك المنصهر لصنع صفيحة فولاذية مجلفنة؛ لفائف الصلب المجلفن المخلوط. يتم تصنيع هذا النوع من لفائف الصلب أيضًا بطريقة الغمس الساخن، ولكن يتم تسخينها إلى حوالي 500 درجة مئوية مباشرة بعد خروجها من الخزان لتشكيل طبقة من سبائك الزنك والحديد. ويتميز هذا النوع من اللفائف المجلفنة بالالتصاق الجيد بالطلاء وقابلية اللحام.

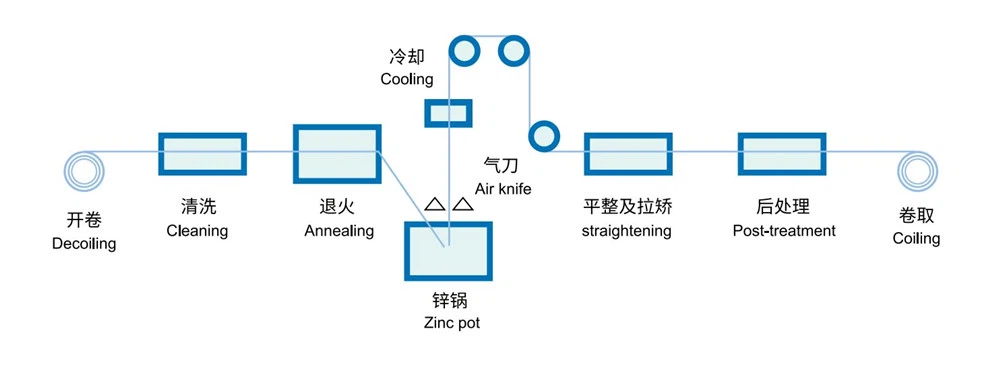

عملية الإنتاج

لحام-مدخل لوبير-معالجة مسبقة-طلاء تمهيدي-طلاء تمهيدي-خبز-تبريد-تبريد-طلاء نهائي-طلاء نهائي-طبقة نهائية-خبز-نقش أو غشاء-خروج لوبير-طلاء

اختبار - لفائف الصلب المجلفن

اختبار الصلابة

اختبار طلاء الزنك

اختبار رش الملح

اختبار التوتر

اختبار السُمك

هل تعجبك هذه الباقة؟

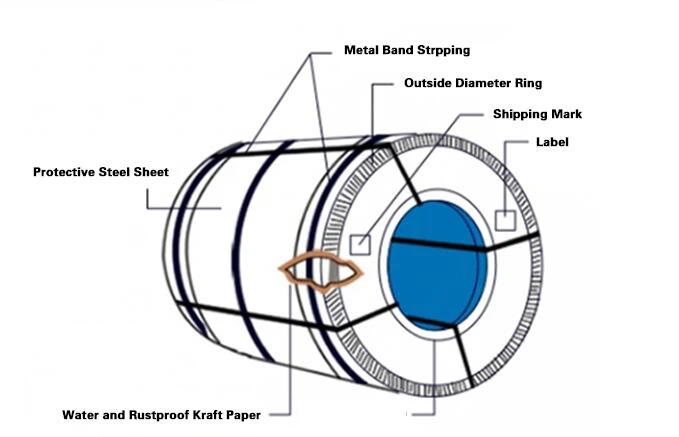

الورق المقاوم للرطوبة، والأغشية البلاستيكية، وألواح التغليف المصنوعة من صفائح الحديد، والأشرطة المعدنية الفولاذية (أربعة أشرطة مربوطة أفقيًا وثلاثة أشرطة طوليًا)، والملصقات وفقًا للمتطلبات.

عبوات التصدير القياسية الدقيقة.