ورشة عمل الهياكل الفولاذية

- One-stop solution for Steel Structure Workshop

- Experienced and Knowledgeable Manufacturer

- Reliable Manufacturing Processes

- High Strong Steel Structure Warehouse

- Affordable Prices

Your Professional Steel Structure Workshop Manufacturers

What is Prefabricated Steel Structure Workshop?

Prefabricated steel structure workshop is an industrial building that uses high-strength steel beams, purlins, and profiled steel plates as core materials and is prefabricated through modular design. Compared with traditional concrete structures, its main components are quickly assembled on-site after precision manufacturing in factories, and can be widely used in manufacturing factories, logistics warehouses, aircraft hangars, agricultural greenhouses, and other scenarios. The construction speed is increased by 40% -60%, making it the preferred choice for modern and efficient industrial facilities.

Our steel structure workshops have different sizes, like 20×20, 30×30, 30×50, 40 x 40, 30×40, 40×60, 50 x 50, 50×100,etc. And we can also customize the size of the steel structure workshop to meet your needs. If your workshop needs a traveling crane, we need to customize the size of the steel frame according to the size of the traveling crane so that can provide you with a one-time package, to save your time and help you save money.

No matter where you are in the world, if you want a satisfying steel structure workshop, we will help you realize it. We will customize a steel structure workshop for you according to your location, wind speed, rainfall, and snowfall.

Contact us get free sample now!

| Main structure | H-section steel | Q345/Q235 steel H beam, Box column is also available |

| اللحام | Automatic Submerged Arc Welding | |

| Rust removing | Shot blasting | |

| surface processing | twice primer and twice finish Alkyd Paint or hot dip galvanized | |

| High strength bolt | Grade 10.9 | |

| Substructure | Angle brace | L50x4, Steel Q235, Process, and painting |

| Cross bracing | Dia.20 round bar, Steel Q235, process and pre-galvanized | |

| Tie bar | Dia.89*3 round pipe, Steel Q235 Process, and painting or pre-galvanized | |

| Batter brace | Dia.12 round bar, Steel Q235 process and pre-galvanized | |

| Ordinary bolt | Galvanized bolt | |

| Roof | Purlin | C channel or Z channel, steel Q235, galvanized |

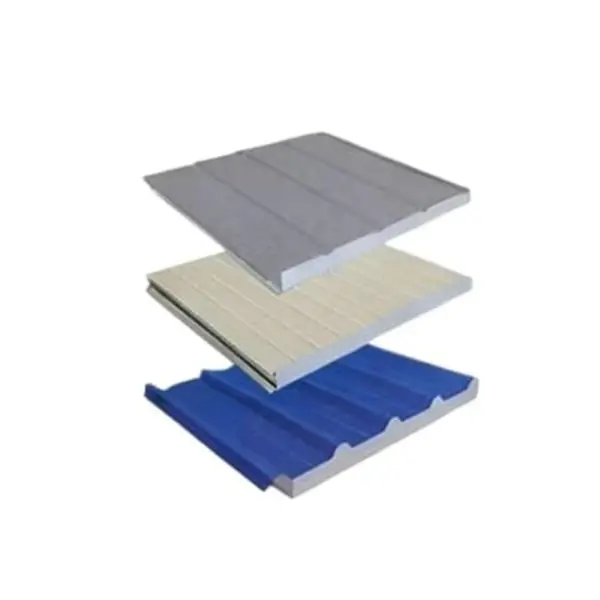

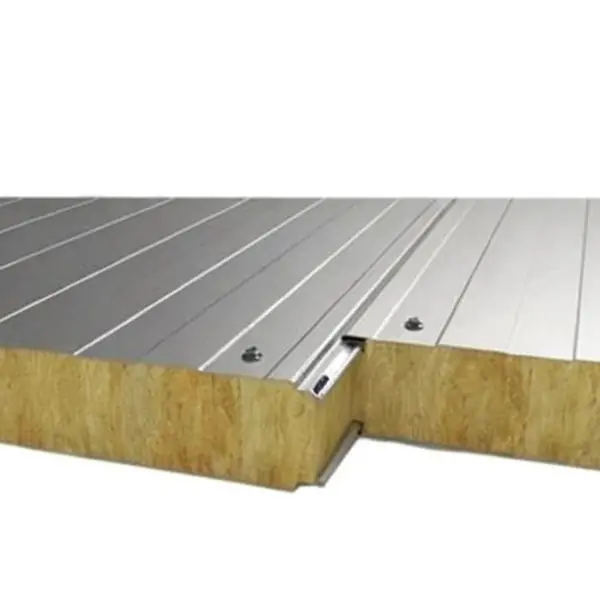

| Roof panel | (50mm, 75mm, 100mm, 150mm) Sandwich panel or corrugated GI color steel sheet | |

| Transparent skylight | 1.2mm FRP/customized | |

| Accessories | Sealant, self-tapping screw, etc. | |

| Edge cover | Made of color steel sheet | |

| Gutter | Made of steel sheet thickness 0.8mm, or PVC | |

| Rainspout | PVC pipe | |

| Wall | Purlin | C channel or Z channel, steel Q235, galvanized |

| Wall panel | (50mm, 75mm, 100mm, 150mm) Sandwich panel or (0.4mm, 0.5mm, 0.6mm, 0.7mm) corrugated GI color steel sheet | |

| Accessories | Sealant, self-tapping screw, etc | |

| Edge cover | Made of GI color steel | |

| Ventilator | unpowered axial-flow ventilator or monitor roof | |

| Door & window | Electric rolling door/sliding door, PVC/Alu. alloy window | |

| Crane | With or without a crane, ranging from 5 tons to 20 tons |

- Embedded parts, (to stabilize the structure of the plant)

- Columns generally use H-shaped steel or C-shaped steel (usually angle steel used to connect two C-shaped steel)

- For beams, generally C-shaped steel and H-shaped steel are used (the height of the middle product is determined according to the span of the beam)For beams, generally C-shaped steel and H-shaped steel are used (the height of the middle product is determined according to the span of the beam)

- Purlin: C-shaped steel and Z-shaped steel are generally used.

- Supports and braces are usually round steel.

- There are two types of tiles, the first is a color steel tile. The second type is composite sandwich board. (Polyurethane or rock wool is sandwiched between the two-layer color-coated board, which plays the role of warming in winter and cooling in summer, and also has the effect of sound insulation and fire prevention).

Steel Structure Workshop Design Considerations

Steel Structure Material

Wall and roof system

Bolt accessories

Steel Structure Workshop Design Considerations

Strength And Durability

Steel is a strong and durable material that can withstand heavy loads and harsh weather conditions. This makes steel structures highly reliable and long-lasting.

Speed Of Construction

Steel structures can be prefabricated off-site, which means that once the foundation is ready, the construction process can be very quick. This can significantly reduce the overall construction time and associated costs.

كفاءة الطاقة

Steel structures can be designed to be energy-efficient by incorporating insulation and other energy-saving technologies. This can lead to lower energy bills and a smaller carbon footprint.

Flexibility In Design

Steel allows for greater flexibility in design compared to traditional materials like concrete. It can be easily shaped and fabricated into various forms, enabling the creation of complex and aesthetically pleasing structures.

Sustainability

Steel is one of the most recycled materials in the world. It can be recycled and reused multiple times without losing its strength, making it an environmentally friendly choice.

Resistance To Fire, Wind, And Earthquake

Steel has inherent fire-resistant properties and can be treated to enhance these characteristics. It also has high strength-to-weight ratio, making it resistant to high winds and seismic activities.

فعالية التكلفة

While the initial cost of steel construction might be higher than some traditional materials, the long-term cost savings in maintenance and energy efficiency can make it a cost-effective solution.

تعدد الاستخدامات

Steel can be used in a wide range of applications, from small sheds to large industrial complexes, making it a versatile construction material.

Non-Combustible

Steel does not burn, which is a significant advantage in terms of safety, especially in areas prone to wildfires or where fire safety is a concern.

الجاذبية الجمالية

Steel structures can be designed to be visually appealing, offering a modern and sleek look that can enhance the appearance of any property.

Lightweight

Compared to other construction materials, steel is relatively lightweight, which can reduce the amount of foundation work required and make transportation easier.

Maintenance-Free

With proper coating and treatment, steel structures require minimal maintenance, which can save time and money in the long run.

High Tensile Strength

Steel has a high tensile strength, allowing it to span greater distances without the need for additional support, which can be particularly beneficial in large open spaces like workshops.

Economical Use Of Space

Steel structures can be designed to use space efficiently, with less material needed for support compared to other construction types.

Steel Structure Workshop Construction

Blueprint and Layout Design: Create detailed architectural blueprints and structural designs. This includes: Floor plans. Location of columns, beams, doors, and windows.

Electrical and plumbing plans.

Load Calculations and Structural Analysis: Engineers perform structural analysis based on factors like wind load, seismic conditions, snow load, and live and dead loads. Advanced software like STAAD Pro or Tekla Structures is often used.

Material Selection: Choose the grade of steel based on requirements like strength, ductility, and corrosion resistance (e.g., galvanized steel, high-strength low-alloy steel).

Prefabrication: Some workshops opt for prefabricated or pre-engineered components to save construction time. These include pre-cut beams, pre-assembled trusses, and pre-made wall panels.

Surface Treatment: Anti-corrosion treatments like galvanizing, powder coating, or painting are applied to fabricated components.

Foundation Construction: Foundations are laid based on the load-bearing capacity and size of the structure.

Common types include:

Isolated Footing: Used for individual columns.

Raft Foundation: A continuous slab for large structures.

Pile Foundation: For weak soil conditions.

Foundation Bolts and Anchor Plates: Bolts and anchor plates are installed to ensure a secure connection between the steel columns and the foundation.

Beam Placement: Horizontal beams (primary and secondary) are installed, connecting the columns to form the skeleton of the structure. Cranes are usually employed to lift and position the beams.

Roof Truss and Rafter Installation: Roof trusses or rafters are placed to form the skeletal structure of the roof. Purlins are installed horizontally across the trusses.

Bracing and Stiffeners: Cross-bracing and stiffeners are added to provide additional strength and stability against lateral forces like wind and seismic activity.

Wall Cladding: Metal panels, sandwich panels, or insulated panels are fixed to the exterior steel framework for walls. Cladding not only provides protection from the elements but also improves the aesthetics of the building.

Insulation and Ventilation: Depending on the use of the workshop, insulation materials like rock wool or polyurethane can be installed. Skylights or ventilators are also added if required.

Plumbing and Drainage: Plumbing lines, water supply, and drainage systems are laid out if required.

Flooring: Depending on the requirements, the flooring could be concrete, epoxy-coated, or industrial tiles.

Non-Destructive Testing (NDT): Techniques like ultrasonic testing, X-ray testing, or magnetic particle inspection may be conducted for weld joints.

Safety Features: Ensure the workshop complies with safety standards and is equipped with fire exits, alarms, and fire extinguishing systems.

Documentation and Maintenance Guide: Provide the client with all documentation, including as-built drawings, safety manuals, and maintenance schedules.

لماذا تختارنا

Our steel shop buildings are designed with the highest-grade American steel, ensuring they’re built to last in any environment.

Versatile Solutions for Any Industry

Our steel structure workshop can be adapted for a wide range of uses, from light industrial workspaces to full-scale production facilities. Our clients rely on us for shop buildings that support diverse industries, including:

Manufacturing Facilities

Create a robust, organized space for production and assembly operations.

Automotive Repair Shops

Design a multi-bay repair shop with ample room for equipment and workspace.

Retail Storage

Securely store inventory and materials with flexible layouts and durable protection.

Woodworking and Fabrication

Our steel buildings provide the perfect environment for heavy-duty machinery and tools.