2507 Edelstahlblech

2507 Edelstahlblech (Duplex 2507 / UNS S31750)

2507 rostfreies Stahlblech, auch bekannt als Duplex 2507 oder UNS S31750, ist ein Super-Duplex-Edelstahl bekannt für seine außergewöhnliche Festigkeit und Korrosionsbeständigkeit. Es enthält 25% Chrom, 7% Nickel und 4% Molybdän, und ist sowohl in warmgewalzt und kaltgewalzt Formen.

Wir bieten Anpassungsmöglichkeiten für unterschiedliche Projektanforderungen, darunter Größe, Form und Oberflächenbeschaffenheit Anforderungen.

Nach Dicke einkaufen

Branchenübergreifende Anwendungen

2507-Edelstahlblech ist weit verbreitet in anspruchsvolle Umgebungen wie zum Beispiel:

Chemie und Petrochemie: Rohrleitungen, Armaturen, Wärmetauscher, Lagerbehälter

Schifffahrt und Offshore: Seewasserausrüstung, Ladetanks, Propeller, Wellen, Ballastwassersysteme

Industrie und Versorgungsunternehmen: Wäschersysteme, REA-Systeme, Rohrleitungen, Absorbertürme, Feuerlöschsysteme

Andere Felder: Papierherstellungsmaschinen, Warmwasserbereiter, Hebezeuge, spiralgewickelte Dichtungen, Drahtprodukte

Produktmerkmale

Hervorragende Korrosionsbeständigkeit gegen Lochfraß und Spaltkorrosion durch Chloride

Hohe Festigkeit und Haltbarkeit mit überragender Zugfestigkeit

Ausgezeichnete thermische Eigenschaften - hohe Leitfähigkeit, geringe Wärmeausdehnung

Einfache Verarbeitung - gute Schweißbarkeit und Verarbeitbarkeit

Geringe Wartung - zuverlässig und langlebig in rauen Umgebungen

Verarbeitung von Dienstleistungen

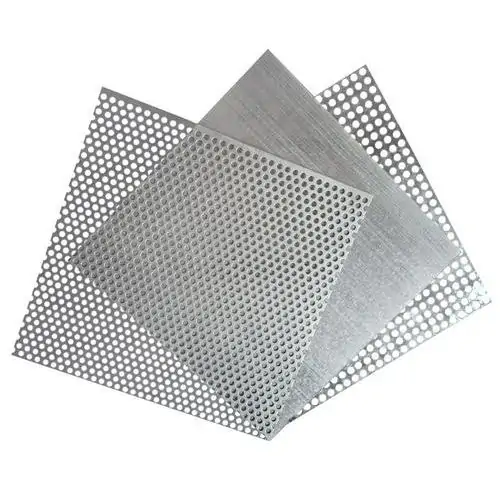

Unser Unternehmen bietet eine Reihe von Bearbeitungsdienstleistungen an, die es Ihnen ermöglichen, die für Ihren spezifischen Bedarf am besten geeignete Option zu wählen. Dazu gehören Laserschneiden, Kantenbearbeitung, Schweißen, Schlitzen, Polieren, Stanzen, Sägen und Scheren, Wasserstrahlschneiden, Plasmaschneiden sowie Biegen und mechanische Bearbeitung.

Eigenschaften von Edelstahlblech 2507

| Breite | 10-3500mm |

| Dicke | 0,1mm-100mm |

| Länge | 1-12m oder auf Länge geschnitten |

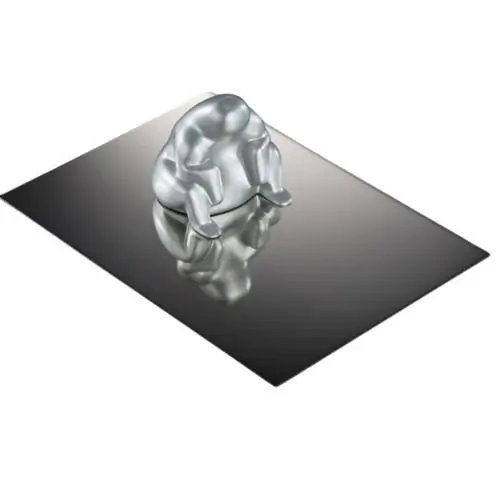

| Oberfläche | 2D, BA, Haarlinie, 2B, Sandstrahlen, Bürste, kariert, geprägt, NO.4, Ätzen, NO.1, NO.8, 8K, Spiegel, etc |

| Standard | ASME SA240 und ASTM A240 |

| Härte | Wir liefern halbhart, weich, viertelhart, hart und hart für dich springen |

| Oberfläche | Nr. 1 Finish, geglüht und gebeizt |

| Verschiedene Formen | Stäbe, Flachstangen, Coils, Folien, Bänder, plattierte Bleche, Kreise, Flachbleche, Feinbleche, Feinblech, Riffelblech |

Super Duplex 2507 Mechanische Eigenschaften

Nachstehend finden Sie die allgemeinen mechanischen Eigenschaften von Super Duplex 2507:

- Zugfestigkeit: Normalerweise zwischen 750 und 1000 Megapascal (MPa) oder 109 bis 145 ksi.

- Streckgrenze: Normalerweise etwa 550 bis 800 MPa oder 80 bis 116 ksi.

- Dehnung: Super Duplex 2507 weist eine höhere Dehnung auf als 25%. Dieses Merkmal misst die Fähigkeit des Materials, sich zu dehnen oder zu verformen, bevor es bricht, und spiegelt seine Duktilität wider.

- Härte: Die Härte von Super Duplex 2507 liegt in der Regel zwischen 250 und 290 Brinell (HB) und bestimmt seine Widerstandsfähigkeit gegen Eindrücken oder Kratzer.

- Schlagzähigkeit: Super Duplex 2507 kann plötzlichen Belastungen oder dynamischen Kräften widerstehen, ohne zu brechen.

Was ist der Unterschied zwischen SAF 2205 und 2507?

1. SAF 2205 und 2507 sind beides Duplex-Edelstahllegierungen.

2. SAF 2205 besteht aus 22% Chrom, 5% Nickel, 3% Molybdän und 0,17% Stickstoff.

3. SAF 2507 enthält 4% Molybdän, 25% Chrom, 7% Nickel und 0,25% Stickstoff.

4. SAF 2507 weist eine höhere Korrosionsbeständigkeit auf, insbesondere gegen Chloride und Seewasser.

5. SAF 2507 besitzt im Vergleich zu SAF 2205 eine höhere Zugfestigkeit und Streckgrenze.

6. SAF 2507 ist in der Regel teurer als SAF 2205.