Your Reliable 321 Stainless Steel Coil Manufacturer

As a kind of austenitic stainless steel coil, 321 stainless steel coil is very popular in many fields and has similar performance with grade 304. It offers excellent weldability, processability, formability, and drawability. Cold working can harden 321 stainless steel coils, eliminating the need for heat treatment. However, it is not suitable for temperatures exceeding 1700°F. As a professional manufacturer of 321 stainless steel coils, yeson steel provides customized sizes, shapes, and grades to meet the specific requirements of your projects.

321 Stainless Steel Coil specifications

| Épaisseur | 0.02 ~ 20mm |

| Largeur | 1 ~ 2500 mm |

| Longueur | coupé à longueur |

| Bord | Fente/fraise |

| Finition de surface | 2B, BA, #4 Brushed, HL, No. 4, Mirror, #8 Mirror, Hairline, No.1 |

Extensive Application

321 stainless steel coils can be used in some industries, which need higher strength, like food industry, aerospace, automotive, electrical industry, cement Industry, gas industry, household products, shaft Industry, power project, generator Industry, medical industry, and hardware fields. In addition, some thermal oxidizers, furnace parts, heating element tubing, heat exchangers, annealing covers, food blenders and mixers, boiler shell, and engine exhaust pipe are all made from 321 stainless steel coils.

Mutiple Features

In addition to its general corrosion resistance, 321 stainless steel coils exhibit outstanding resistance to oxidation and intergranular corrosion. They possess high creep and stress rupture properties, along with excellent low-temperature toughness. Apart from the feature of ductility, 321 stainless steel coils are also easy to machined and fabricated.

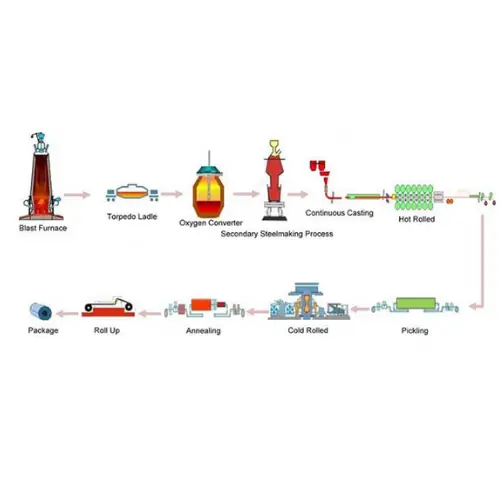

Professional Processing

Our 321 stainless steel coils are all processed by professional procedures, including testing, cutting, forming drilling, grinding, and machining.

Strict Testing

To ensure the quality of our 321 stainless steel coils, we conduct strict and advanced tests for hardness, pitting resistance, flattening, hydrostatic, radiography and impact, etc.

In short, when welding 321 stainless steel, it is recommended to use a filler metal that matches or is similar to the base metal. ER321 is a commonly used filler metal designed specifically for welding 321 stainless steel. It contains titanium to prevent sensitization during welding.