Tôle d'étanchéité en galvalume

La tôle de toiture Galvalume est populaire pour les applications commerciales, résidentielles, agricoles et industrielles. Elle est recouverte d'une couche d'alliage aluminium-zinc qui lui confère une résistance supérieure à la corrosion et à la chaleur.

En raison de ses performances supérieures, il s'agit d'une option idéale pour les propriétaires, les entrepreneurs, les architectes et les investisseurs. HBYeson Steel dispose d'une large gamme de tôles de couverture en métal galvalume dans des tailles et des designs qui répondent à vos besoins. N'hésitez pas à nous contacter pour plus de détails !

En tant que fabricant leader de tôles d'étanchéité galvanisées, HByeson Steel dispose de seize machines de formage de tôles ondulées, qui peuvent produire plus de 20 formes et modèles de toitures. Nous adhérons à des normes de qualité strictes afin de garantir que les tôles ondulées galvalume répondent aux exigences des clients.

Spécifications de la tôle de couverture en galvalume

| Épaisseur | 0,15 mm-0,8 mm |

| Largeur totale | 700 mm-1 250 mm |

| Largeur effective | 600 mm-1 050 mm |

| Contenu du revêtement Al-Zn | Aluminium (Al) 55%, zinc (Zn) 43,5%, silicium (Si) 1,5% |

| Épaisseur du revêtement Al-Zn | 60 g/㎡-185 g/㎡ |

| Longueur | Selon vos besoins |

| Standard | GB, JIS, ASTM, EN |

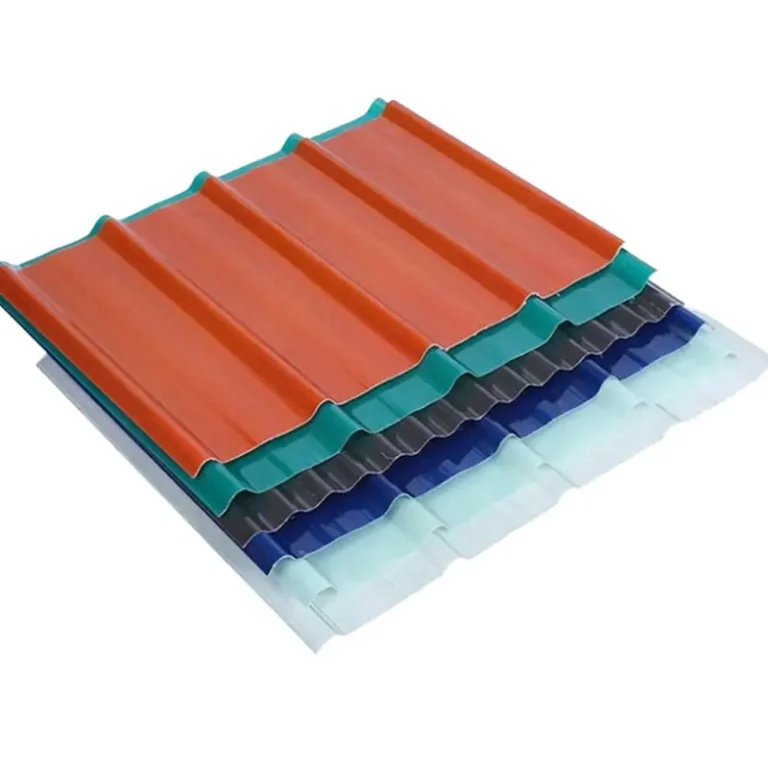

| Traitement de surface | Passivation, résistance aux empreintes digitales, huilage, pré-peinture, etc. |

Contrôle de la qualité et auto-inspection

Yeson Steel dispose d'un équipement de test avancé et d'une équipe professionnelle. Yeson Steel contrôle strictement la qualité à chaque étape de la production, y compris l'inspection des matières premières, le test d'épaisseur et de largeur du produit, le test de revêtement de zinc, le test de pliage en T, le test d'impact, le test de traction, le test de pulvérisation de sel et le test d'emballage sur les bobines d'acier exportées, ce qui garantit sa performance et sa qualité intégrées.

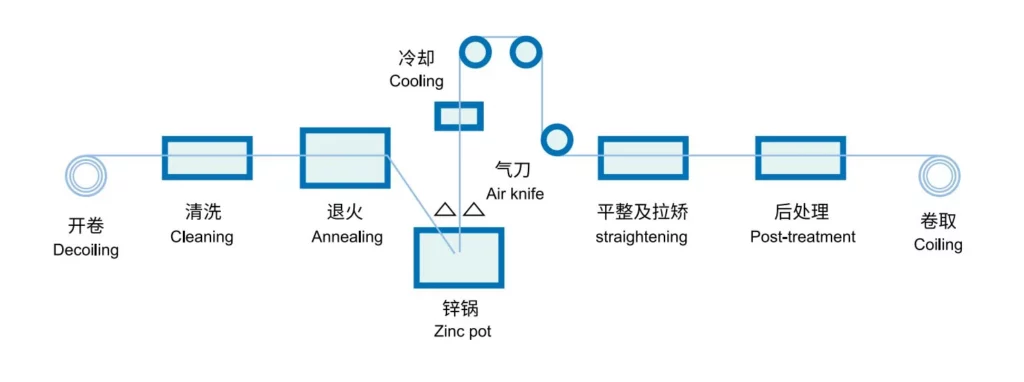

Processus de fabrication des bobines d'aluzinc

1)Déshuilage-Nettoyage-Annealing-Pot de zinc-Refroidissement-Couteau à air-Dressage-Post-Traitement-Enroulement

2) Traitement de surface :

Chromé / skin pass/ huilé/Anti-doigts-AFP

3) Caractéristiques de l'aluzinc

■ Formabilité

Atteindre pour le laminage, l'estampage, le cintrage et d'autres formes de traitement.

■ Résistance à la chaleur

Les produits galvanisés à chaud ordinaires sont généralement utilisés à une température ne dépassant pas 230 ℃ et changent de couleur à 250 ℃. Toutefois, les feuilles de zinc aluminé peuvent être utilisées pendant longtemps dans un environnement de 315 ℃.

■ Haute réflectivité

La réflectivité est supérieure à 0,70, meilleure que les 0,65 spécifiés par EPA Energy Star. C'est un matériau de construction idéal pour les économies d'énergie.

Avantages de la tôle de couverture en galvalume

1. Résistance supérieure à la corrosion

La couche d'aluminium offre à l'acier galvalume une excellente résistance à la corrosion. Lorsque le zinc est usé, l'aluminium forme une couche dense d'oxyde d'aluminium, empêchant les substances résistantes à la corrosion de continuer à corroder l'intérieur. La résistance à la corrosion de la tôle GL est donc trois fois supérieure à celle de la tôle galvanisée. La durée de vie de la tôle GL est de 2 à 6 fois supérieure à celle de la tôle GI dans les mêmes conditions.

2. Réflectivité thermique élevée

Son coefficient de réflexion est deux fois supérieur à celui de la tôle galvanisée, ce qui permet de réduire la température intérieure en été et la consommation d'énergie des climatiseurs. Cette caractéristique en fait un produit idéal pour les climats chauds.

3. Résistance aux hautes températures

La tôle de couverture GL présente une bonne résistance à la chaleur et peut supporter des températures élevées de plus de 300 degrés. Elle peut donc être utilisée pendant longtemps à des températures élevées.

4. Surface lisse et apparence uniforme

La tôle de couverture Galvalume est lisse, de couleur blanc argenté avec des paillettes uniformes. Elle est belle et peut être utilisée directement. C'est pourquoi elle est largement utilisée à des fins commerciales et résidentielles.

5. Formabilité et adhérence élevées

L'adhérence entre le revêtement GL et la peinture est bonne, ce qui le rend facile à peindre. Il présente également une grande facilité de mise en forme. En d'autres termes, il est facile à estamper, à découper, etc.

Ces caractéristiques de la toiture en galvalume la rendent populaire dans de nombreux projets. Chez Wanzhi Steel, nous nous engageons à vous proposer des tôles de toiture de qualité. De plus, l'inspection de la qualité par une tierce partie est acceptable. Ainsi, quel que soit l'endroit où vous utiliserez les tôles de toiture, vous pouvez essayer les panneaux de toiture GL.

Utilisations des panneaux de toiture en galvalume

Les tôles de toiture en acier Galvalume sont utilisées pour les projets d'installation de toitures résidentielles et commerciales.

1. Bâtiments commerciaux - hôpitaux, écoles, magasins, bâtiments gouvernementaux, etc.

2. Projets résidentiels - maisons privées, appartements, maisons de fortune, garages, etc.

3. Applications industrielles - entrepôts, usines, etc.

4. Utilisations agricoles - granges, entrepôts, serres, etc.

FAQ

Le galvalume est-il meilleur que l'aluminium pour les toitures ?

Si l'on considère la résistance de l'acier, le galvalume est plus résistant que les tôles d'aluminium, car l'aluminium est plus souple. En outre, les tôles en galvalume sont beaucoup moins chères que les tôles en aluminium. aluminium tôles. C'est pourquoi les toitures en galvalume sont meilleures et plus populaires.

Quelle est la durée de vie d'une toiture en galvalume ?

En général, la durée de vie d'une toiture en métal galvalume est supérieure à 50 ans.

Les panneaux de toiture en galvalume peuvent-ils être peints ?

Oui, il peut être peint si vous le souhaitez. Le revêtement en galvalume a une bonne adhérence. N'oubliez pas d'utiliser des peintures adaptées.

La tôle de couverture en galvalume est-elle plus chère ?

En général, elle est plus chère que la tôle de couverture galvanisée (à épaisseur de revêtement égale). Mais le prix de la toiture métallique GL n'est pas le plus élevé. En outre, il peut durer plus de 50 ans. Sa longue durée de vie le rend plus rentable.