Pre-Painted Galvanized Steel Coil and Galvalume Steel Coils (AZ150, G345A, PVDF) are very suitable for construction or other facilities in extreme environments and are extremely resistant to corrosion and weather. In addition, high-strength steel sheets have been widely used abroad, with relatively hot-dip galvanized iron alloys, hot-dip galvanized aluminum alloys, hot-dip galvanized aluminum alloys and galvanized zinc.

Generally used color steel coils are hot-dip galvanized and hot-dip Galvalume. They are indistinguishable from each other in appearance, and can only be seen on the sign of the color package. The substrate of the color steel coil is hot-dip galvanized, and the raw material of the hot-dip galvanized is a cold-rolled sheet. The cold-rolled sheet is plated with zinc. Now galvanization is generally hot-dip galvanized, and there is very little electroplating, so color steel The coil is a cold-rolled sheet.

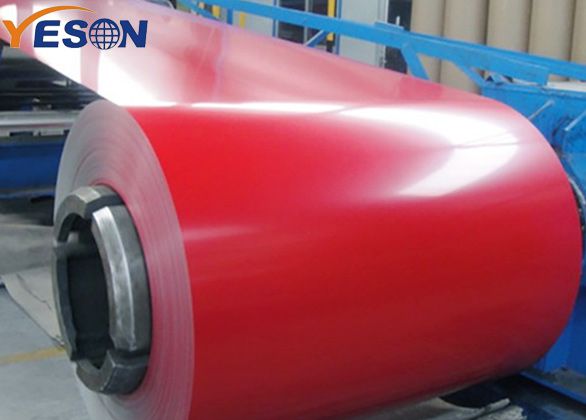

Color coating coil is the mainstream in the field of construction. This product has a variety of outstanding properties. Its high strength can be used as a structural panel of ceiling furnaces. It is resistant to compression and bending, rich in color, and has a variety of colors to meet the different requirements of users. With the continuous development of various industries, the number of users for color coatings is also increasing, but with the continuous rise of manufacturers.

There are also a variety of PPGI steel coils available on the market, and many users cannot make good choices. The production process is to roll the hard coil into a zinc pot to make its surface coated with metal zinc. The production process of hot-dip galvanizing can ensure the adhesion of metal zinc on the surface of the steel plate. The zinc layer can provide excellent corrosion resistance to extend the life of the product.