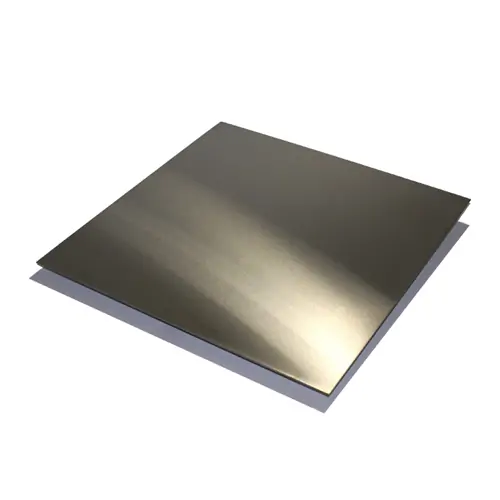

403 Stainless Steel Sheet

403 Stainless Steel Sheet Supplier in China

403 stainless steel sheet is a martensitic stainless steel widely used across various industrial applications. It is non-magnetic and can be hardened through heat treatment to achieve enhanced mechanical properties. We also provide customization services for size, type, and surface finish to meet diverse project requirements.

Key Features of 403 Stainless Steel Sheet

A standout characteristic of 403 stainless steel is its high hardness, making it ideal for applications requiring wear resistance and durability. It performs exceptionally well in components with cutting edges or those subjected to abrasive conditions. When properly heat-treated, these sheets exhibit high strength and good fatigue resistance. Although their corrosion resistance is lower than that of austenitic stainless steels, they still offer reliable performance in mildly to moderately corrosive environments. This combination of hardness, strength, and moderate corrosion resistance also contributes to excellent wear behavior.

Common Applications of 403 Stainless Steel Sheet

403 stainless steel sheets are used in a variety of sectors. In the medical field, they are often found in surgical instruments, syringes, and needles. They are also commonly used in the production of cutlery and cookware for kitchen applications. The material is suitable for high-strength fasteners such as screws and bolts. Additionally, it is widely employed in power generation equipment, including steam and gas turbine blades. Other typical applications include bushings, buckets, valve parts, missile and rocket components, as well as compressor and turbine parts.

In summary, 403 stainless steel sheet is a versatile and essential material in many industrial fields. Its balance of hardness, strength, and corrosion resistance ensures reliable performance across various demanding applications. Customizable sizing and processing options further improve its adaptability to specialized needs.

403 Stainless Steel Sheet Advantage

Corrosion-Resistance

403-panel maximum corrosion resistance is achieved by polishing and hardening. It can create an oxide film with high adhesion.

Oxidation Resistance

It can withstand oxidation up to 760°C. Continuous service shouldn’t allow temperatures to rise above 649-704°C.

Packaging & Delivery

HByesonsteel is an expert in safe shipping, on-time delivery, and high-quality manufacturing that lowers customers’ overall costs.

Product Marking

Before sending the goods out for delivery, we mark them with information about the product, such as the batch number, client’s name, trademark, etc.

Testing Methods: Destructive and Non-Destructive

- Mechanical Testing such as Tensile and Elongation

- Test for Buckling and Crushing

- Test with Eddy Current

- Performing a Corrosion Test

- Radiographic Examination

- Recognizing Positive Materials

- Chemical Analysis

Processing ways for 403 stainless steel sheet

Here are several standard processing methods for 403 stainless steel sheets:

- Hot Rolled: The sheets are shaped at high temperatures, resulting in a versatile material.

- Cold Rolled: This process imparts a smoother surface finish while maintaining dimensional accuracy.

- Cutting: The sheets can be accurately cut to the desired size and shape.

- Forming: The sheets are pliable enough to be shaped into various forms.

- Drilling/Machining: Precision holes and intricate designs can be created through drilling and machining.

- Grinding: This process refines the surface texture for improved aesthetics and performance.

- Polishing: Sheets can undergo polishing to achieve a smooth, reflective surface.

- Testing: Rigorous testing ensures that the sheets meet quality and performance standards.

In conclusion, 403 stainless steel sheets are an essential material with a variety of applications in the American industrial landscape. Their high hardness, strength, and corrosion resistance make them a reliable choice across different sectors. The versatile processing methods further enhance their adaptability to specific requirements.

| Yield strength (strain 0.200 %) | Elastic modulus | Poisson’s ratio | Elongation at break (in 50 mm) | Hardness, Rockwell B | Izod impact (tempered) |

| 45000 psi | 27557-30458 ksi | 0.27-0.30 | 25.00% | 80 | 75.2 ft-lb |

| C | Si | Mn | S | P | Cr |

| 0.15max | 0.50max | 1.00max | 0.030max | 0.040max | 11.50~13.00 |