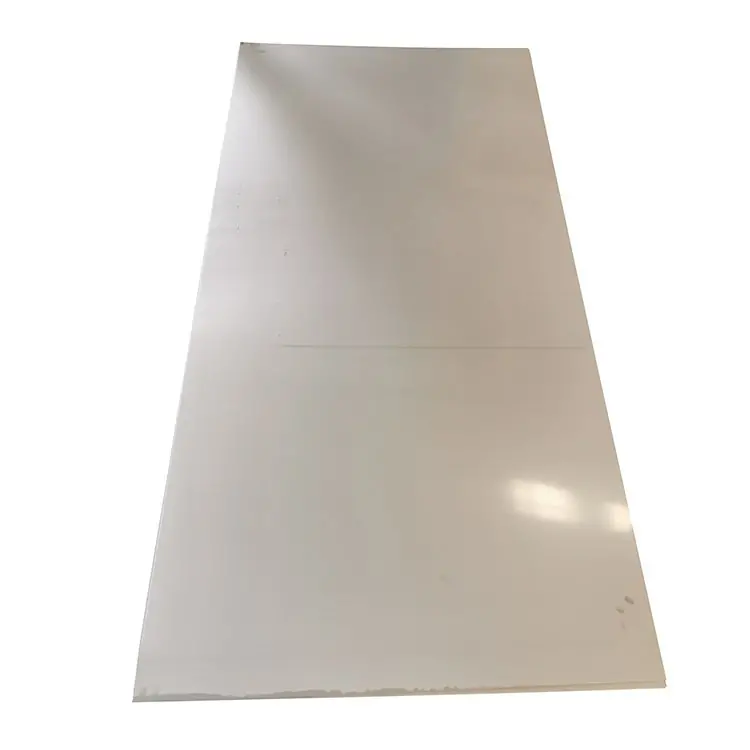

431 Stainless Steel Sheet

The 431 stainless steel sheet is a martensitic, heat-treatable grade that offers superior corrosion resistance compared to conventional martensitic stainless steels. With excellent oxidation resistance and high torque strength, Grade 431 delivers optimal toughness, wear resistance, and tensile properties—making it an ideal choice for high-stress components such as bolts and shafts.

YesonSteel’s 431 stainless panels perform exceptionally well in marine environments, and also resist a wide range of organic chemicals, petroleum-based compounds, and acidic conditions. Available in various diameters, surface finishes, and specifications, our Grade 431 products can be tailored to meet your specific needs. Contact us today to request a competitive quotation.

| Product Parameters: Stainless Steel Sheet/Plate | |||

| Width | 10mm~2500mm | ||

| Thickness | 0.2mm~100mm | Thickness tolerance | +/-0.03mm |

| Standard | ASTM/ASME 240/480,JIS 4305,DIN EN 10088-2 | ||

| Surface | 2B,BA,8K,NO.1,NO.4,NO.3,hairline,checkered,gold ,black ,rose gold,etc | ||

| specification | 1000*2000/L,1219*2438/L,1250*2500/L,1500*3000/L1500*6000/L,1800*6000/L,2000*6000/L2200*6000L | ||

| Grade | 304 304DQ 201 301 304L 304H 309S 310S 316L 316TI 317L 321 347 347H 430 410 410S 420 420J2 430 430LNT 430J1L 434 436L 439 441 443 444 904L 2205 2507 S32750 S32760 445J2 442etc | ||

431 SS Sheet Specifications

Stainless Steel 431 conforms to the following standards.

- AISI: 431

- AMS: 5628, S-18732

- ASTM: A276, A473, A511, A579, A580

- BS: 431S29, BS EN10204

- DIN: 1.4057; DMS-1565

- MIL S: -18732, -8967

- UNS: S43100

431 Stainless Steel Sheet Processing Service

- 431 SS Sheet Cutting: Flame, laser, wire, shear, plasma, etc.

- 431 SS Sheet Slitting

- 431 SS Sheet Etching

- 431 SS Sheet Welding

- 431 SS Sheet Bending

- 431 SS Sheet Polishing

- 431 SS Sheet Embossing

- 431 SS Sheet Bead Blasted

- 431 SS Sheet Color Coating

431 SS Sheet Main Field of Application

Grade 431 stainless steels are frequently used for the following:

- Nuts and Bolts

- Valves, Shafts, Axles

- Pumps, Propeller Shafts,

- Beater Bars

- Pump Shafts

- Fasteners

- Marine Systems

- Cookware, label ware

- Laboratory Equipment

- Surgical Instruments

- Aircraft Components

- Household Appliances

431 Stainless Steel Sheet Key Properties

Corrosion-Resistant

- The sheets have greater resistance to salt water, but less resistance to tropical water.

- Overall corrosion resistance is comparable to 304 steels.

- Smooth-surfaced function well under a tempered and harsh environments.

Suitability

- It has excellent tension and torsional strength

- The alloy is applied to various market segments

| Product | Stainless Steel 431 Sheet |

| Thickness | 0.3-10.0mm, or customize as per request |

| Width | 1000mm – 3500mm, etc |

| Length | 2000mm – 6000mm, etc |

| Standard | JIS, AISI, GB, EN, etc |

| Surface | Embossed, 2D, NO.1, NO.8, 8K, Sand Blast, Etching, etc |

| Package | Wooden boxes, Wooden pallets, Wooden crates, Shrink-wrapped, Carton boxes, etc. |

| Edge | Mill Edge/ Slit Edge |

| Technique | Hot-rolled, Cold-rolled |

431 Stainless Steel Sheet Technique

Welding

Due to the potential for cracking, welding grade 431 stainless steel is challenging.

Pre-heating materials between 200 to 300°C prior to welding is advised.

Machining

431 is easily machineable with all operations like turning, drilling, etc

All machining must be done in accordance with tool type, speed, and feeds.

Cold Bending

Type 431 SS panel is simple to bend, draw, spin, and more.

Hot Bending

Grade 431 steel is heated to 2100-2200 F for optimal results.

Work materials at no lower than 1650 F (900 C).

Forging

Heat the 431-grade panel uniformly to between 1150° and 1200°C.

Do not soak; instead, start forging right away.

Hardening

Hardening 431 can be done through heating at 980–1065 °C.

It can hold for approximately half an hour and then harden by quenching in air or oil.

Tempering

Temper for the desired qualities. It can be heated to between 590° and 680°C as needed.

Annealing

Grade 431 can be heated to between 620 and 660°C (1200–1500 F) and then air-cooled.

431-Grade SS Sheet Technical Data

| Grade | Carbon | Manganese | Silicon | Phosphorus | Sulfur | Chromium | Nickel |

| 431 | 0.20% | 1.00% | 1.00% | 0.04% | 0.03% | 15 – 18.00% | 1.25 -2.50% |

| Condition | Tensile Strength(MPa) | 0.2% Yield N/mm² | Elongation % | Izod KCV J | Hardness Brinell (HB) |

| *T | 850-1000 | 635 | 11 | 63 34- 63 20 | 248-302 |

| Grade | 431 | |

| Density (kg/m3) | 7800 | |

| Elastic Modulus (GPa) | 200 | |

| Mean Coefficient of Thermal Expansion (μm/m/°C) | 0-100°C | 10.2 |

| 0-315°C | 12.1 | |

| Thermal Conductivity (W/m.K) | at 100°C | 20.2 |

| Specific Heat | 460 | |

| Electrical Resistivity | 720 |