440C Stainless Steel Sheet

440C stainless steel sheet is a martensitic stainless steel known for its high strength and excellent wear resistance. While this grade is generally not recommended for welding due to its tendency to air-harden and risk of cracking, it performs optimally in hardened and tempered conditions. YesonSteel provides customized options for 440C stainless steel sheets, including various forms, alternative stainless steel grades, and a wide selection of sizes to meet diverse project requirements.

Features of 440C Stainless Steel Sheet

This hardenable high-chromium steel offers notable strength, good resistance to fresh water, mild acids, and food environments, as well as outstanding wear performance. For optimal durability and corrosion resistance, we recommend that 440C stainless steel sheets be used in a hardened, tempered, and passivated state.

Applications of 440C Stainless Steel Sheet

Thanks to its exceptional hardness and strength, 440C stainless steel sheet is widely used across industrial, machinery, and tooling applications. Common uses include:

Surgical instruments

Cutting tools, chisels, and knife blades

Ball bearings and valve components

Measuring devices and valve seats

Rolling element bearings

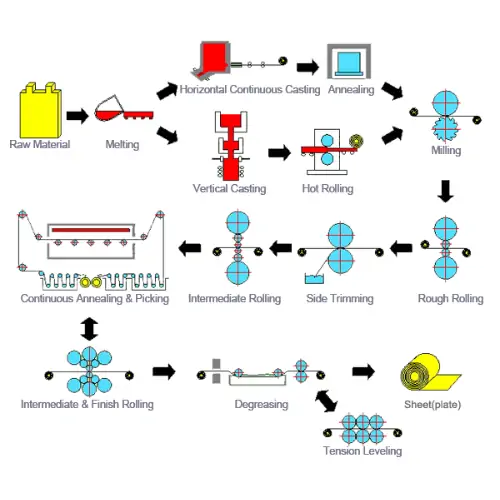

Metals Processing

We offer a comprehensive suite of professional metal processing services to meet your exact specifications. Our capabilities include flame cutting, plasma cutting, waterjet cutting, plate laser cutting, and tube laser cutting for precise shaping. We also provide saw cutting, precision plate sawing, shearing, and grinding for accurate sizing and finishing. For parts requiring forming or thermal treatment, our press brake/forming and thermal processing services are available. Additionally, we specialize in tube cutting & chamfering and precision milled super square edge preparation. Every service can be customized to your project's unique requirements.

440c Stainless Steel Sheet Heat Treatment

440C stainless steel sheet is processed through a controlled heat treatment sequence of annealing, hardening, and tempering. The annealing stage involves heating the material to 800–900°C (1472–1652°F) followed by slow cooling. For hardening, the steel is heated to 1000–1050°C (1832–1922°F) and then rapidly cooled. Finally, tempering is performed at temperatures typically ranging from 150–300°C (302–572°F) to improve the material’s toughness and achieve the desired mechanical properties.

Our 440C stainless steel sheet meets multiple international standards, including ASTM A276, ASTM A480, ASTM F899, AMS 5630 Chem Only, and AISI (440C).

How to heat treat 440c stainless steel at home?

Heat treating 440C stainless steel at home requires annealing at 800-900°C (1472-1652°F), followed by hardening at 1000-1050°C (1832-1922°F) and quenching in oil or air. Finally, temper the steel at 150-300°C (302-572°F) for improved toughness.

Is 440 stainless steel good for knives?

Yes, 440 stainless steel is commonly used in the manufacturing of knives and is known for its excellent hardness, wear resistance, and corrosion resistance. It is a high-carbon martensitic stainless steel that offers good edge retention and is relatively easy to sharpen. 440 stainless steel, particularly 440C, is often favored by knife makers and enthusiasts for its combination of hardness, corrosion resistance, and affordability. However, it’s important to note that the performance of a knife depends on various factors beyond the steel type, such as heat treatment, blade geometry, and overall design.

Is 440c stainless steel magnetic?

Yes, 440C stainless steel is magnetic. It belongs to the martensitic stainless steel family, which is generally magnetic due to its microstructure. The high carbon content and heat treatment process of 440C stainless steel contribute to its magnetic properties. This magnetic characteristic can be useful in certain applications, such as magnetic knife holders or when working with magnetic tool holders or devices.

How hard is 440c stainless steel?

440C stainless steel is known for its excellent hardness. It is a high-carbon martensitic stainless steel that can achieve high levels of hardness through proper heat treatment. When properly hardened, 440C stainless steel can reach a hardness of approximately 58-60 HRC (Rockwell Hardness Scale). This high hardness makes it well-suited for applications where wear resistance and edge retention are crucial, such as in high-performance knives, cutting tools, and bearings.