Heat-Resistant Stainless Steel

What is Heat-Resistant Stainless Steel?

Heat-resistant stainless steel is a specialized type of stainless steel engineered to maintain its mechanical strength and structural integrity under elevated temperatures. Unlike standard stainless steels, it can withstand high heat without significant loss of strength or deformation. Typically non-magnetic, this category includes ferritic and austenitic steels, as well as nickel-based alloys, all designed to perform reliably in demanding thermal environments.

Why is Heat-Resistant Stainless Steel Outstanding?

Heat-resistant stainless steel stands out due to its exceptional combination of properties:

High mechanical strength even at elevated temperatures

Excellent ductility and workability for ease of fabrication

Good weldability and formability across a wide range of applications

Strong resistance to grain boundary corrosion

Superior creep strength and oxidation resistance at high temperatures

This unique balance of heat resistance, strength, and corrosion protection ensures consistent performance across varying operating conditions.

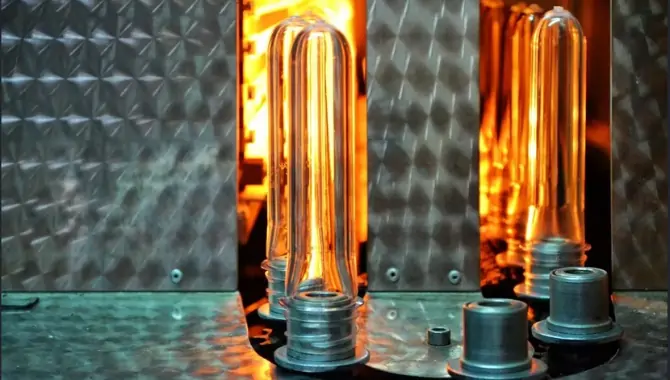

Applications of Heat-Resistant Stainless Steel

Thanks to its durability and versatility, heat-resistant stainless steel is widely used in industries that demand long-term exposure to high heat and corrosive environments. Common applications include:

Industrial equipment: furnace and boiler components, furnace baskets and trays, conveyor belts, annealing bells, muffles, retorts, burners, pusher furnaces, and combustion chambers.

Energy and process industries: steam boilers, heat exchangers, fluidized bed combustors, and incineration plants.

Manufacturing and materials: glass production, ceramics, pulp processing, and food industry equipment.

Automotive and aerospace: exhaust systems, turbocharger parts, and high-performance engine components.

Chemical and petrochemical sectors: equipment exposed to aggressive thermal and chemical conditions.

Grades Options

Surface Treatment

To cater to specific requirements, we offer a variety of surface finishes for heat-resistant stainless steel, including 1D (hot rolled, annealed, and pickled), 2B (cold rolled, annealed, and pickled), 2E (mechanically descaled and pickled), 1C (hot rolled, annealed, and non-descaled), 2C (cold rolled, annealed, and non-descaled), and 2R (cold rolled and bright annealed).

Welding Methods

Thanks to its excellent weldability, we provide several common welding procedures for heat-resistant stainless steel, such as MIG/MAG, TIG, or electrode welding.

304 vs 316 stainless steel heat resistance: which is better?

Between the two, 316 stainless steel generally has better heat resistance, making it more suitable for applications that involve higher temperatures. However, the specific choice depends on the maximum operating temperature of the application and other factors such as corrosion resistance requirements and cost considerations.

For applications where temperatures may exceed 870°C (1600°F), 316 stainless steel would be a more appropriate choice due to its higher heat resistance. It’s also a preferred option for applications in aggressive environments where corrosion resistance is critical.

If the operating temperature is well below 870°C (1600°F), 304 stainless steel may suffice and is often more cost-effective. Additionally, if the application demands good general corrosion resistance but does not require the higher heat resistance of 316, 304 can be a suitable choice.

In summary, if you need superior heat resistance and corrosion resistance, 316 stainless steel is generally the better option. However, for many applications with lower operating temperatures and less demanding corrosion resistance needs, 304 stainless steel remains a popular and cost-effective choice.