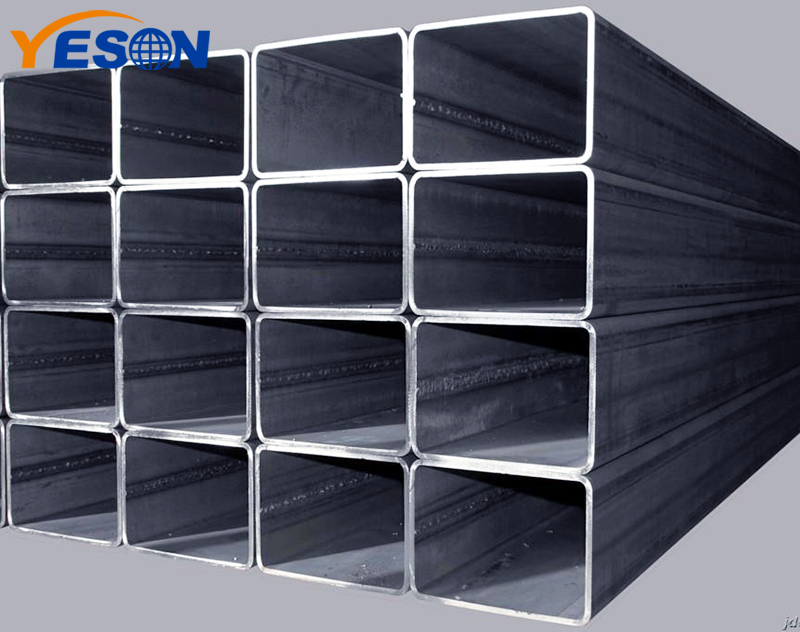

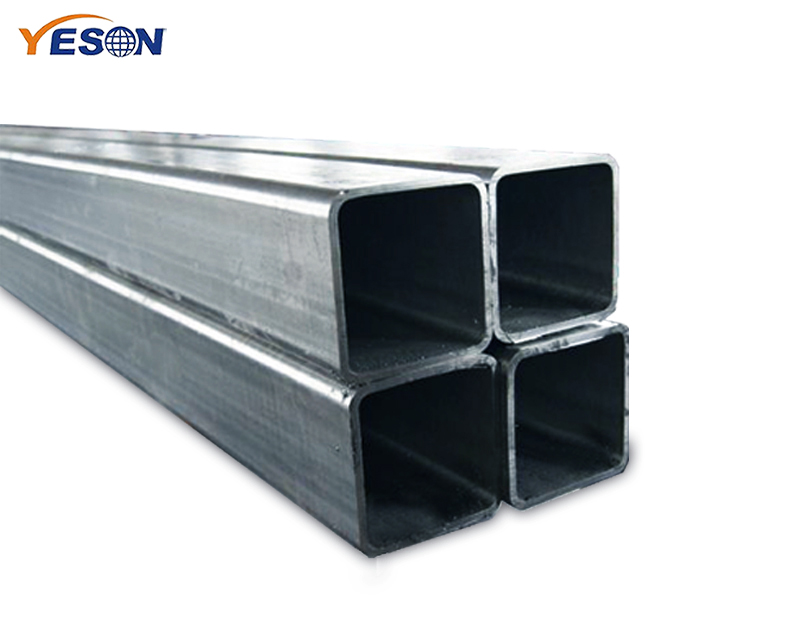

Hot-dip galvanized square pipe: It is a square pipe made by welding steel or steel strip after crimping. On the basis of this kind of square pipe, the square pipe is placed in the hot-dip galvanizing pool and a series of chemical reactions are formed. The production process of square tube and hot-dip galvanized square tube is relatively simple, but the production efficiency is still high, and there are many varieties and specifications. However, this kind of square tube requires very little equipment and capital, and is suitable for small galvanized square tube manufacturers. Production, but in terms of strength, the strength of this steel pipe is much lower than that of seamless square pipes.

Cold-galvanized square pipe: It uses the principle of cold galvanizing on the used square tube to make the square tube have anti-corrosion function. Unlike hot-dip galvanizing, cold galvanized paint is mainly anti-corrosion through electrochemical principles, so it must be ensured The full contact of zinc powder and steel produces electrode potential difference, so the surface treatment of steel is very important.

The difference between cold galvanized and hot-dip galvanized square pipes: galvanized square pipes are divided into two categories: hot-dip galvanized square pipes and cold-dip galvanized square pipes. Hot-dip galvanized square pipes include wet dry method, lead-zinc method, and redox method; The surface of the cold-dip galvanized zinc layer is very smooth and compact, with uniform structure, good mechanical function and corrosion resistance, and the zinc consumption is 60%-75% lower than that of hot-dip galvanizing.