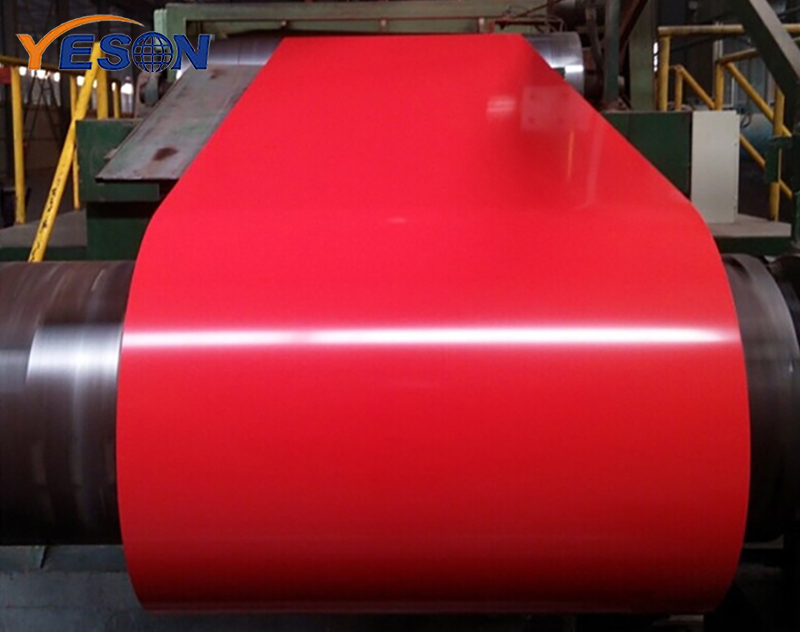

As the color-coated coil is widely used in everyone's daily life, its use characteristics and advantages have been recognized by everyone. For better application, let us learn about the coating technology of the color-coated board.

The product quality of color-coated panels not only depends on the basic properties of the substrate and coating, but also depends on the production technology and operation control technology. Operation control technology has a great influence on the physical properties and surface quality of color-coated board products. From the analysis of production technology, the focus of production control technology includes cleaning treatment, chemical coating treatment, painting (including primary coating, fine coating), and curing. , Color-coated board production adopts two-coating and two-coating production technology.

In order to ensure the coating quality of color-coated products, the surface of the substrate must be degreasing, dust-removing, rust-removing and other preliminary treatments before coating. This is the first step to ensure coating technology and the basis for ensuring the quality of color-coated products. jobs. The purpose is to remove the anti-rust oil, rust, dust, etc. attached to the surface of the substrate, and perform chemical coating treatment on the surface of the clean substrate to form a networked chemical conversion film with Cr6+ and Cr3+ as the basic framework, and increase the substrate and coating. The adhesion between the substrates improves the corrosion resistance of the substrate and the durability of the coating. The quality of the work determines the quality of the coating, and directly affects the flexibility and impact resistance of the coating and other physical indicators. It determines the coating adhesion of the color-coated coil product. The purpose of primary coating, fine coating, and curing is to coat the coating on the surface of the substrate, and use heating to volatilize the organic solvent of the coating, so that the organic coating is closely combined with the substrate.

The above is about the coating technology of color-coated coil. You can use it as a reference. You must operate in accordance with the regulations in the future use process to avoid unnecessary troubles and achieve the expected results. I hope the above content will help you.

Previous: None