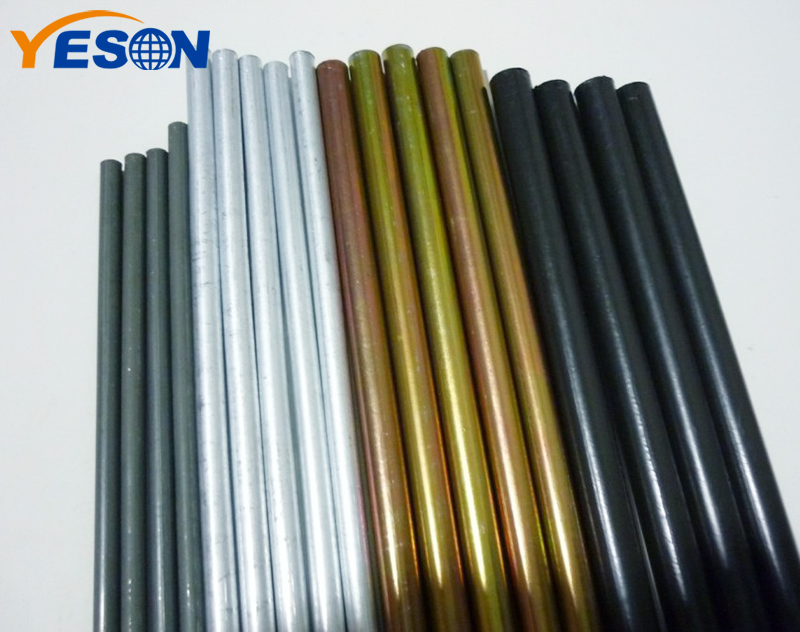

Galvanized steel round pipe is a welded steel pipe with hot-dip or electro-galvanized layer on the surface. Galvanizing can increase the corrosion resistance of steel pipes and prolong the service life. Galvanized pipes are widely used. In addition to being used as pipeline pipes for ordinary low-pressure fluids such as water transportation, gas, oil, etc., they are also used as oil well pipes and oil pipelines in the petroleum industry, especially in offshore oil fields, oil heaters and condensation of chemical coking equipment. Pipes for coolers, coal distillation oil washing AC converters, trestle pipe piles, support frames for mine tunnels, etc.

Classification of galvanized steel pipes: galvanized steel pipes are divided into cold galvanized steel pipes and hot galvanized steel pipes. The cold-galvanized steel pipe has been banned, and the latter has also been temporarily used by the country. In the 1960s and 1970s, internationally prosperous countries began to develop new types of pipes, and galvanized pipes were banned. Hot dip galvanized steel pipes are widely used in fire protection, electric power and highway.

Hot-dip galvanized steel pipe: Hot-dip galvanized pipe is to make the molten metal react with the iron matrix to produce an alloy layer, thereby separating the matrix and the plating layer. Hot-dip galvanizing is to stop pickling the steel pipe first, in order to remove the iron oxide on the outside of the steel pipe, after pickling, stop washing through the ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then send it into Hot dip plating bath.

Hot galvanized has the advantages of even coating, strong adhesion and long service life. The complex physical and chemical reactions between the hot-dip galvanized steel pipe substrate and the molten plating solution constitute a zinc-iron alloy layer with a corrosion-resistant and tight structure. The alloy layer is integrated with the pure zinc layer and the steel pipe substrate, so its corrosion resistance is strong.