The hot rolling of the seamless steel pipe is rolling at a temperature above the crystallization temperature, and conversely, for cold rolling, it is carried out below the crystallization temperature.

Hot-rolled seamless steel pipes are divided into low-boiler steel pipes and medium-high boiler steel pipes, alloys, stainless steel, petroleum-degraded steel pipes, geological steel pipes and other steel pipes.

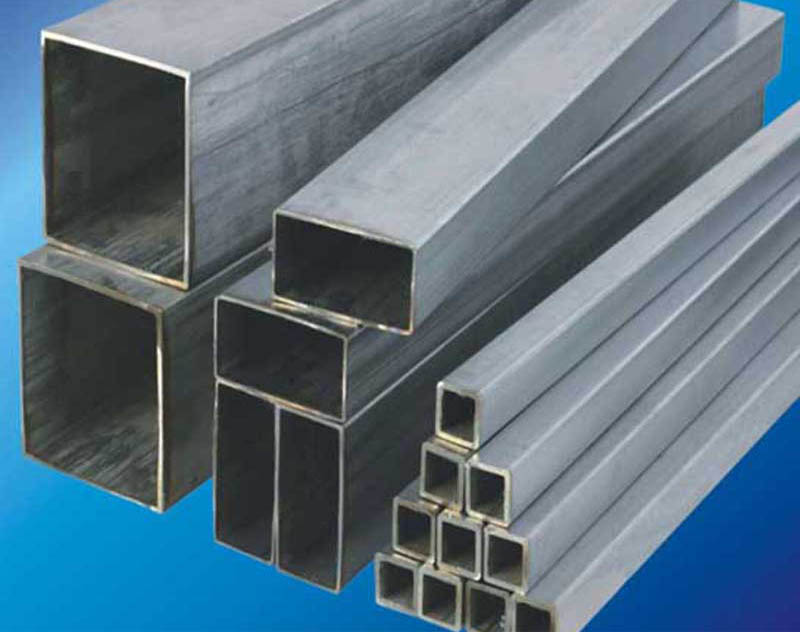

Cold-rolled (dial) seamless steel pipe is divided into general steel pipe, low and medium pressure boiler steel pipe, high pressure boiler steel pipe, alloy steel pipe, stainless steel pipe, petroleum cracking pipe, other steel pipes, and also includes carbon thin-walled steel pipe and alloy thin-walled steel pipe. Stainless steel thin-walled steel pipe and special-shaped steel pipe. The outer diameter of hot-rolled seamless pipe is generally larger than 32mm, the wall thickness is 2.5-75mm, the outer diameter of cold-rolled seamless steel pipe can be up to 6mm, the wall thickness can be up to 0.25mm, the outer diameter of thin-walled pipe can be 5mm, and the wall thickness is less than 0.25mm. Cold rolling has higher dimensional accuracy than hot rolling.

Generally used seamless steel pipe: it is made of 10, 20, 30, 35, 45 and other high-quality carbon steel 16Mn, 5MnV and other low-alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot-rolled or cold-rolled. Seamless pipes made of low carbon steel such as 10 and 20 are mainly used for fluid conveying pipes. 45, 40Cr and other medium carbon steel seamless pipes are used to make mechanical parts, such as the force parts of automobiles and tractors. Generally, seamless steel pipes are required to ensure strength and flattening test. The hot rolled steel pipe is delivered in a hot rolled state or a heat treated state; the cold rolling is delivered in a heat treated state.