Galvanized coils can be operated according to the normal paint spraying methods (brush coating, roller coating, spraying). Hot-dip galvanized coils will not rust for several years, and cold-galvanized coils will rust within three months. The advantages of hot-dip galvanizing is that it has strong anti-corrosion ability and good adhesion and hardness of galvanized layer.

The electrolytic device is used to degrease and pickle the workpiece and put it into a solution containing a zinc salt, and connect the negative electrode of the electrolytic device. A zinc plate is placed on the opposite side of the workpiece to be connected to the positive electrode of the electrolytic equipment, and the power is turned on. It is a light gray transition metal.

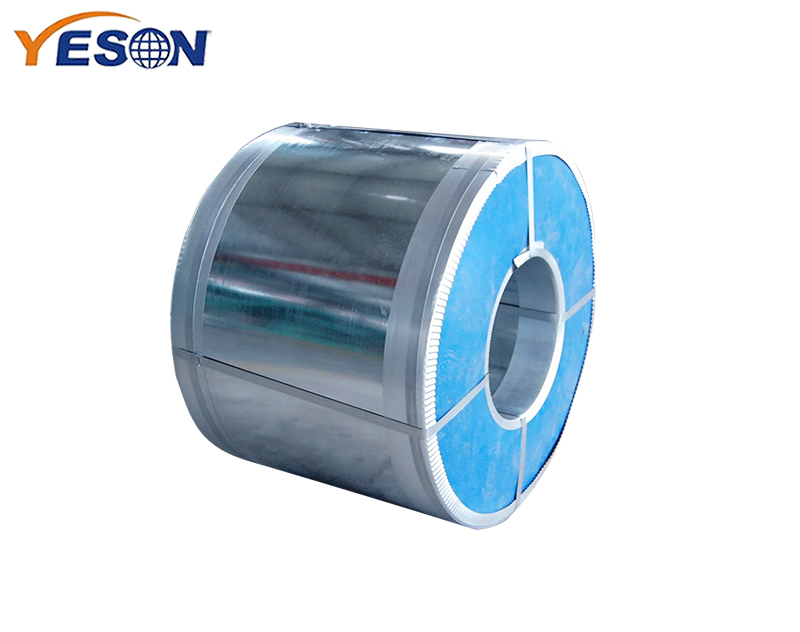

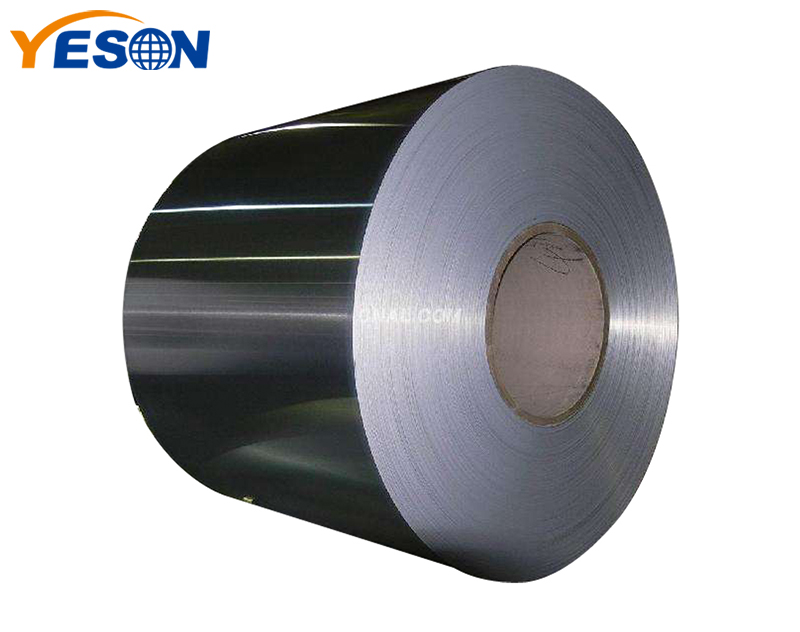

Zinc is the fourth "common" metal. Production and sales of various hot-dip galvanized steel coil springboards of various lengths; leasing of steel pipes, fasteners, marine scaffolding; construction of color steel coil construction and ship scaffolding; manufacturing and processing Clips and other marine accessories. The manufacturing cost is relatively low. Hot-dip galvanizing can obtain a very thick galvanized layer, which includes a zinc-iron alloy layer. The zinc-iron alloy layer has more excellent corrosion resistance. After putting some auxiliary materials, the metal structure is immersed in the galvanizing bath In the process, a zinc layer is attached to the metal member.

The advantages of hot-dip galvanizing are that it has strong anti-corrosion ability and good adhesion and hardness of galvanized layer. There are two types of hot-dip galvanizing: flower galvanizing and flowerless galvanizing. The flowering must be hot-dip galvanizing. The flowerless and galvanizing are similar. It depends on experience to distinguish. Thus, both the substrate and the plating layer are combined.