According to the form of post-treatment, galvanized mild steel sheet is divided into categories of passivation, oiling, passivating oiling, lacquer sealing, phosphating or no treatment.

(1) Passivated galvanized mild steel sheet. The passivated galvanized sheet is to reduce the generation of white rust under wet conditions, and a passivation protective film is further coated on the surface of the product after galvanizing. According to the type of passivation film, it is divided into hexavalent chromium passivation, third-order chromium passivation, chromium-free passivation and other products, generally not used for zinc-iron alloy plates.

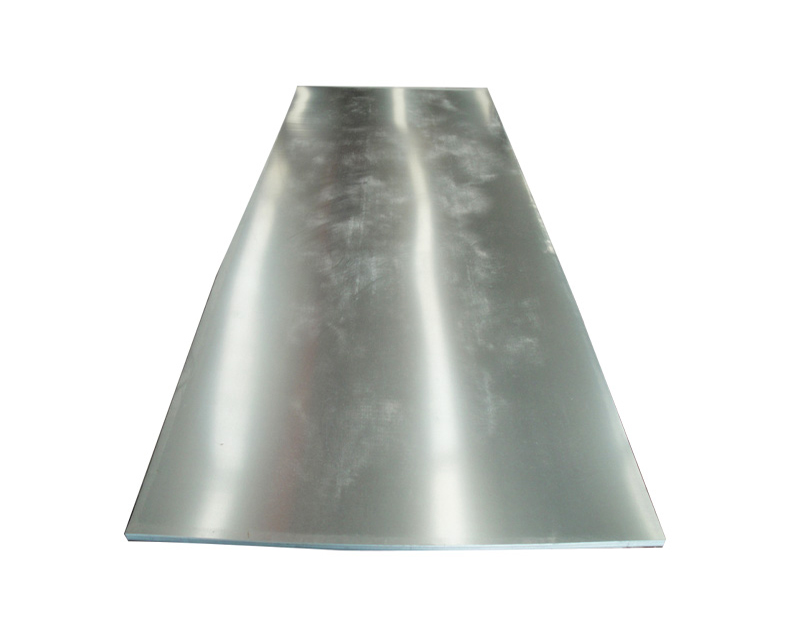

Surface treatment method of galvanized mild steel sheet

(2) Oil-coated galvanized mild steel sheet. The purpose of oiling is also to prevent the product from getting wet and producing white rust. However, the anti-rust oil is very volatile or wiped, so it can only play a role before use. Oiling methods include electrostatic oiling and roller oiling. If you want to prevent the product from generating white rust during use, it is best to use passivation and oiling. Color-coated substrates are more suitable for light oil treatment. The oil applied can be cleaned and removed in the pre-treatment of the color coating line.

(3) Paint-sealed galvanized mild steel sheet. The lacquer seal is commonly referred to as a fingerprint-resistant product. In order to prevent galvanized products from leaving fingerprints during processing, a thin layer of fingerprint-resistant protective film is coated on the surface of the galvanized product, which can also improve the product's corrosion resistance and Product coating performance. Suitable for the special needs of home appliances.