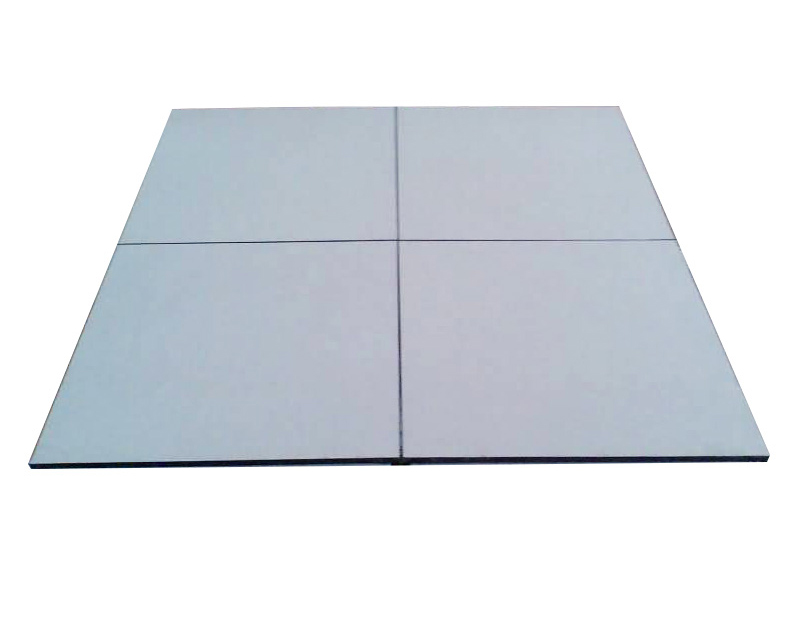

Aluminum Zinc Sheet is mainly used for reinforced concrete water-stop steel plate structures, dams and other large projects. Such as: tunnels, subways, dams, culverts, construction joints in water conservancy and hydropower projects, high-rise building basements, underground parking lots and other major engineering construction joints. Steel plate water-stop steel plate plays an important role in infrastructure projects, underground facilities, tunnels, sewage treatment plants, water conservancy, subways and other projects.

According to the production process, Aluminum Zinc Sheets are divided into two types: cold-formed thin-walled steel sheet piles and hot-rolled steel sheet piles. Cold-formed steel sheet piles are made of thinner plates and processed by cold-formed forming units. The production cost is low and the price is cheap, and the fixed-length control is also flexible. However, due to the simple processing method, the thickness of each part of the pile body is the same, and the cross-sectional size cannot be optimized, which leads to an increase in steel consumption; the shape of the lock part is difficult to control, the joint is not tightly buckled, and the water can not be stopped; It can produce products with low strength grades and thinner thicknesses; and the stress generated in the cold bending process is relatively large, and the pile body is easy to tear during use, and the application has greater limitations. The hot-rolled steel sheet pile is formed by a billet mill, a rail beam rolling mill or a rolling mill through high-temperature rolling. It has the advantages of standard size, superior performance, reasonable cross-section, and high quality. Hot-rolled steel sheet piles can be divided into U-shaped, Z-shaped, straight-line, H-shaped and tubular types and their combined forms from the cross-sectional shape.

Installation requirements for Aluminum Zinc Sheet:

1. Use 30cm wide and 3mm thick water-stop steel plate, the steel plate is mechanically cut, 25mm on both sides are bent into a 45° angle, the water-stop plate is installed in the middle of the concrete wall thickness or the thickness of the board, and the center line of the water-stop plate is slightly lower than the concrete construction The position of the seam, so that the center line of the water stop after the concrete construction seam is chiseled coincides with the construction seam, 150mm on each side. First fix two 12# steel bars perpendicular to the bottom plate, place the water-stop steel plate in the two steel bar cores, pass through a steel bar to penetrate the water-stop steel plate, and weld the water-stop ring on the steel bar to connect the water-stop ring and the stop Fully welded heels between steel plates. Steel water-stop steel plates and rubber water-stop steel plates are not as good as rubber water-stop steel plates. The later processing is troublesome, so use rubber water-stop steel plates as much as possible for construction; control according to the measured horizontal line before installation, and draw the line to find the level. , The water stop plate is installed according to the elevation;

2. When the root of the water-stop steel plate is in place, the decorations between the steel plates should be reduced as much as possible. The interface between the steel plates can be lap welding, and the lap length should be greater than 400mm. The welding seam needs to be welded by arc welding. Welding, the steel plate is overlapped 5cm, double-sided welding, the weld should be welded without leakage, no porosity, and slag inclusion. The water-stop plate is fixed by spot welding of steel bars, and the steel bars that are cut when the water-stop steel plate is installed are connected to the water-stop steel plate by lap welding for reinforcement. The post-pouring belt water-stop steel plate is connected with the water-stop steel plate in the horizontal construction joint of the wall to form a closed water-stop steel plate;

3. Questions about the policy of the demolition target, whether it is a degree steel water-stop steel plate or a vertical steel water-stop steel plate, the policy of the two-curved surface demolition target must be facing the water surface;

4. Steel plate weld inspection: For welds with a length less than 500, check 1 for each; for welds with a length of 500 to 2000, check 2 for each; for welds with a length greater than 2000, check 3 for each.

Maintenance method of Aluminum Zinc Sheet:

1. During transportation and construction, prevent machinery and steel bars from damaging the water-stop steel plates.

2. The water-stop steel plate shall not be exposed to the open air for a long time to prevent rain, and do not contact with highly polluting chemical substances.

3. Methods of fixing the water-stop steel plate include: fixing with additional steel bars, fixing with special fixtures, fixing with lead wires and templates, etc. When perforation is required, the water-stop steel plate can only be selected in the edge installation area of the water-stop steel plate, and other parts shall not be damaged.