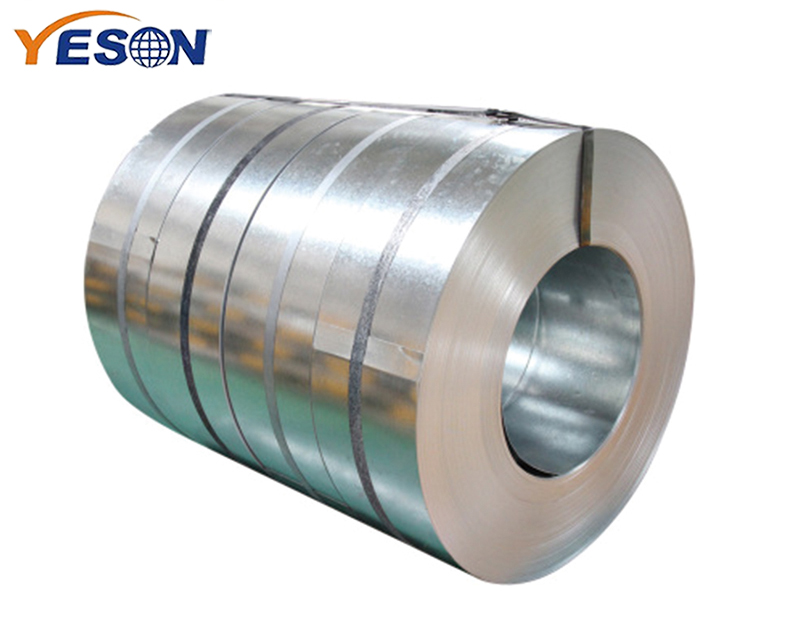

Galvanized Hot Rolled Steel Coil has the advantages of low cost and good appearance due to its ideal corrosion resistance, forming, electric welding and spraying, etc., and it is widely used in manufacturing industries such as construction, small cars, and household appliances. During the production of galvanized steel sheets, strips and forehead wrinkles will continue to appear, which endangers the quality of the material. The customer's use must be controlled.

1. Strip highlighting

The appearance of the strip-shaped highlight defects is usually heavy along the cold rolling, and it is spread in a canine-toothed strip, which looks like a scratched defect. The difference is that the number of strip-shaped defects is never fluid, so it is very influential in analogy. fluidity. The cause of this defect is due to material defects.

Control countermeasures:

(1) Improve the composition plan of the ironmaking process, and adjust the manganese-sulfur ratio of the iron liquid at the demonstration sites; in addition, formulate a seasonal and two-cool water flow rate system to distinguish the disturbance caused by seasonal factors throughout the year.

(2) In the rolling process, the upper part of the five teeth is never coated, and the lower half of the mold is coated.

(3) Improve the improvement of the processing technology and weaponry of the previous hot-dip galvanizing process, and minimize the natural environment caused by the continuous emergence of scratches by the weaponry. In addition, cold rolling production starts with a large cold rolling force that reduces the number of passes, which replaces the natural environment caused by the destruction of the natural environment due to the rolling material that is roughly cut.

2. Forehead wrinkle defects

Some of them resemble the wrinkles on a person's forehead, so they are called forehead wrinkles. The hot-dip galvanized Hot Rolled Steel Coil contains horizontal pattern defects and the liquidity of the zinc liquid, and the formation of Coriolis air mass in the process of the re-quenching system. The cold-rolled coil elements can easily cause the forehead wrinkle defects of the galvanized steel sheet.

Control countermeasures:

(1) Properly increase the zinc liquid temperature and hot-rolled strip speed, or reduce the aluminum water content in the zinc liquid and increase the aspect ratio of the demister, so as to expand the liquidity of the zinc liquid in the demister area.

(2) Increase the press-in amount of the bumpy roller, and increase the bumpy effect and adverse effects. Increase the number of bending areas, reduce the total width of the bending areas, and alleviate forehead wrinkles.

(3) Reducing the tensile strength of tension and correction is to replace the total plastic deformation.

(4) The annealing temperature of hot-rolled strip steel is fairly controlled for galvanized Hot Rolled Steel Coil.