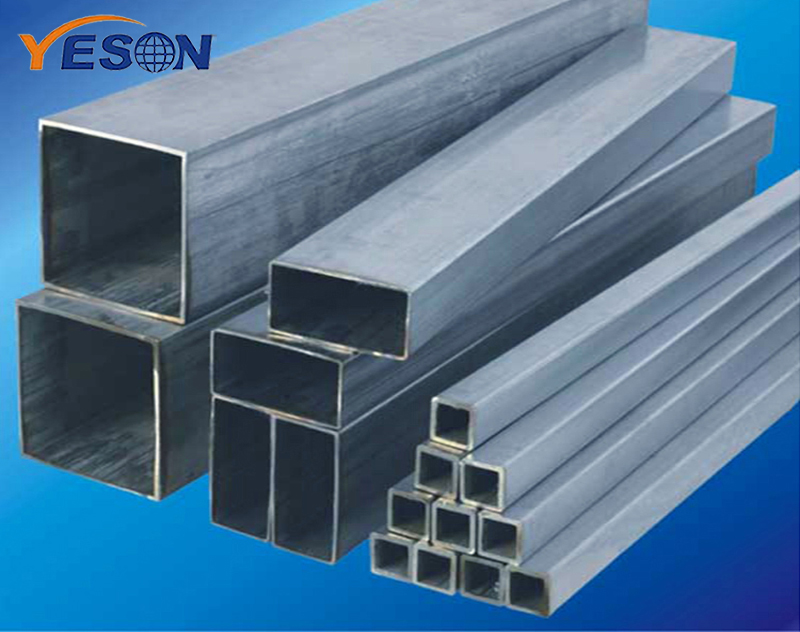

Galvanized square pipe, which has the double advantages of corrosion resistance and long service life, and the price is relatively low, so its utilization rate is also getting higher and higher, but some users do not weld galvanized pipe Pay attention, it causes some unnecessary troubles, so what problems should be paid attention to when welding galvanized pipes?

1. The premise is to polish

The galvanized layer at the welding place must be polished off, otherwise bubbles, trachoma, false welding, etc. may occur. It will also make the welds brittle and the rigidity will drop.

2. Welding characteristics of galvanized square tube

The galvanized square tube is generally coated with a layer of zinc on the low carbon steel, and the galvanized layer is generally 20um thick. Zinc has a melting point of 419 ℃ and a boiling point of about 908 ℃. In welding, zinc melts into a liquid floating on the surface of the molten pool or at the root of the weld. Zinc has greater solid solubility in iron. Zinc liquid can penetrate the weld metal deeply along the grain boundary. Low melting point zinc constitutes "liquid metal embrittlement". At the same time, zinc and iron can form brittle compounds between metals, these brittle phases reduce the plasticity of the weld metal, and cracks occur under the effect of tensile stress. If welding fillet welds, especially T-joint fillet welds, it is easier for penetration cracks to occur. When the galvanized steel pipe is welded, the zinc layer on the surface and edge of the groove will be oxidized, melted, and transpired under the effect of arc heat, so that white smoke and steam will be announced, which is very likely to cause weld pores. The melting point of ZnO formed by oxidation is high, above 1800 ° C. If the parameter is too small during welding, ZnO will cause slag inclusion. At the same time, because Zn becomes a deoxidizer, FeO-MnO or FeO-MnO SiO2 low melting point oxide slag. Secondly, because of the transpiration of zinc, a lot of white smoke is announced, which has an impact on the human body and a harmful effect. Therefore, the galvanized layer at the weld must be polished away.

3. Welding process control

The preparation of galvanized steel pipe before welding is the same as that of general low-carbon steel. It is necessary to pay attention to carefully handle the groove size and the adjacent galvanized layer. For penetration, the groove dimensions must be appropriate, generally 60 ~ 65°, with a certain gap, generally 1.5 ~ 2.5mm; in order to reduce the penetration of zinc into the weld, before welding, the galvanizing in the groove can be Weld after the layer is removed.

In actual work, the gathering and beveling is selected, and the blunt-edge process is not used for gathering control. The two-layer welding process reduces the possibility of under-welding. The electrode should be selected according to the base material of the galvanized steel pipe. Generally, low-carbon steel is generally used because of its ease of operation.

Steel pipe welding method: When welding the multi-layer welding seam, try to melt the zinc layer and make it vaporize and evaporate to escape the weld, which can greatly reduce the liquid zinc remaining in the weld. When welding fillet welds, the zinc layer is also melted as much as possible to vaporize and evaporate and escape the weld. The method is to move the end of the electrode forward by about 5 ~ 7mm. When the zinc layer is melted Return to the original position and continue to weld forward. In the case of horizontal and vertical welding, if the short slag electrode such as J427 is used, the tendency to undercut will be very small; if the back and forth transportation technique is used, the defect-free welding quality can be obtained.