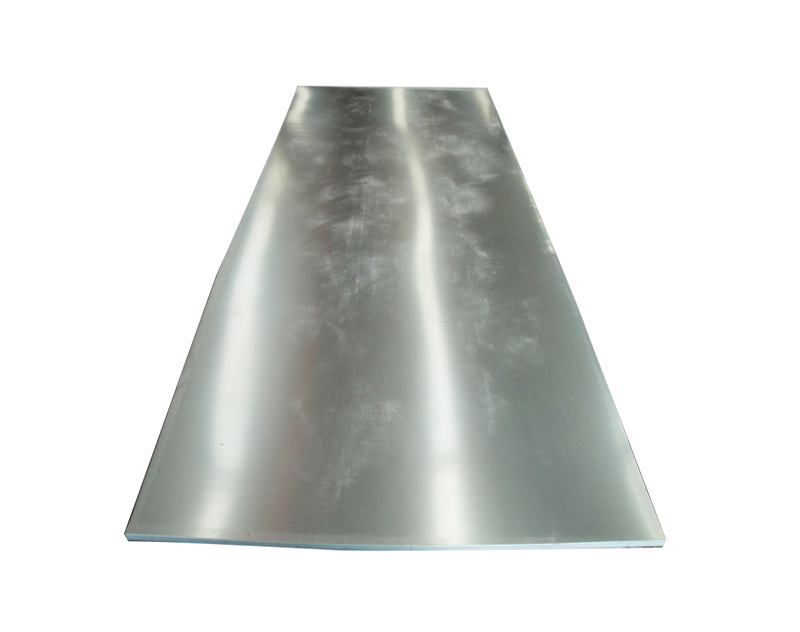

Galvanized Mild Steel sheet refers to a steel sheet coated with a layer of zinc on the surface. Galvanizing is an economical and effective anti-corrosion method that is often used. About half of the world's zinc production is used in this process. Galvanized steel sheet is to prevent corrosion on the surface of the steel sheet and prolong its service life. The surface of the steel sheet is coated with a layer of metal zinc. This kind of galvanized steel sheet is called galvanized sheet.

Hot-dip galvanized sheets are mainly used in construction, home appliances, automobiles, machinery, electronics, light industry and other industries.

The commonly used steel grades for hot-dip galvanized steel sheet are: general commodity coil (CQ), structural galvanized sheet (HSLA), stamped galvanized sheet (DQ), deep-drawing hot-dip galvanized sheet (DDQ), and baking hardened hot-dip galvanized sheet (BH), dual phase steel (DP), TRIP steel (transformation induced plasticity steel), etc.

There are usually two cooling methods for hot-dip galvanized sheets: air cooling and water cooling.

With the development of the industry, hot-dip galvanized steel sheets have been used in many areas. The advantage of hot-dip galvanizing is that it is durable in anti-corrosion years, and it has always been a very anticipated anti-corrosion treatment to adapt to a wide range of environments.

The principle of hot-dip galvanizing in a hot-dip galvanizing plant: clean the iron parts, treat them with solvents, dry them, and immerse them in the zinc solution. The iron reacts with the molten zinc to form an alloyed zinc layer.

The thickness of the hot-dip galvanized alloy layer mainly depends on the chemical composition such as the silicon content of the steel, the size of the cross-sectional area of the steel, the roughness of the surface of the galvanized steel sheet, the temperature of the zinc pot, the time of galvanizing, cooling speed, cold rolling deformation, etc.